The aggregate impact value is defined

as a relative measure of the resistance of an aggregate to sudden shock or

impact, which (in some aggregates) may differ from its resistance to a slow compressive

load.

The aggregate impact value test is an

important test of aggregates. It is done to obtain the resistance

and impact of aggregates (stones). In this test a machine is used,

which is called impact testing machine.

The aggregates have sufficient

toughness to resist their disintegration due to impact. This property is measured

by aggregate impact value test. So that aggregate impact

value test is used to determine the relative measure of the resistance

of aggregate to sudden shock or impact, which in

some aggregate differs from its resistance to a slowly applies

compressive load.

The advantages of aggregates impact value

test are that the apparatus and procedure of the test are simple. With

this test, we can obtain the resistance and impact of aggregates (stones)

even in field condition. The test can be done in a short period

whether it is at construction site.

Impact value test determines

the amount of energy absorbed by a material during fracture. This absorbed

energy gives a measure of toughness of a given material and acts as a tool to

study temperature-dependent brittle-ductile transition. It is used to determine

whether the material is brittle or ductile in nature.

Impact testing machine is commonly used to

determine the service life of a part or material. It evaluate an object's

capacity to withstand high-rate compressive loading. Impact resistance can be among

the most challenging qualities to measure which is measured by impact testing

machine. The capacity evaluate this characteristic is particularly useful in

assessing product liability and safety.

Aggregate Impact Value Test Procedure as per IS: 2386 Part-4 (1963)

Hi friends, you are welcomed in the world

of Civil Allied Gyan. Here

I have explained about Aggregate Impact Test. Read definition,

apparatus, IS code, procedure, observations, formula, result

and lab report about aggregate impact value test.

- Impact testing machine

- Cylinder

- A straight metal tamping rod of circular cross-section 16 mm in diameter, 45 cm to 60 cm in length and rounded at one end.

- IS Sieves

- Oven

- Weighing balance

- IS: 2386 (Part 4) -1963, Methods of test for aggregate for concrete

- IS: 383: 1970, Specification of coarse aggregate and fine aggregate from natural source for concrete

- IS: 9377: 1979, Specification of apparatus for aggregate impact value test

Procedure of Aggregate Impact Value Test:-

- Take test samples of aggregates passing through 12.5 mm IS sieve and retained on 10 mm IS sieve.

- Dry theme in an oven for 4 hours at a temperature of 100 °C to 110 °C and then cool at room temperature.

- Fill the aggregates up to about 1/3 full in the cylindrical measure and tamp for 25 times with rounded end of the tamping rod.

- Fill the rest portion of the cylindrical measure by two layers (1/3 + 1/3) and tamp each layer for 25 times.

- Cut off the overflow of aggregates in cylindrically measure by tamping rod using its straight edge or by a knife.

- Then weigh the entire aggregates sample of the measuring cylinder with an accuracy to 0.01 g.

- Transfer the aggregates carefully from the cylindrical measure into the cup, which is firmly fixed in position on the base plate of machine.

- Then tamp it for 25 times with rounded end of the tamping rod.

- The hammer is raised until its lower face be 38 cm above the upper surface of aggregate in the cup and allow it to fall freely on the aggregates.

- The test sample (aggregate) is subjected to a total of 15 such blows each being delivered at an interval of not less than 1 second.

- Then remove the crushed aggregate from the cup and sieve the whole of it on 2.36 mm IS sieve until no significant amount passes through the sieve.

- Weigh the fraction (aggregates) passing through the 2.36 mm IS sieve with an accuracy to 0.1 g.

- Repeat the above steps with other fresh sample.

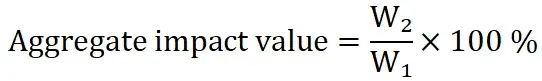

- Let the original weight of the oven dry sample of

aggregates be W1 g

and the weight of fraction (aggregates) passing 2.36 mm IS sieve be W₂ g.

- Then aggregate impact value is expressed as the percentage of fines formed in terms of the total weight of the sample.

Observations:-

Table: Impact

value of sample aggregates

Observation

|

Trail 1

|

Trail 2

|

Total weight of the aggregate filling the cylindrical

metal measures W₁ g

|

||

Weight of aggregate passing

through 2.36 mm sieve W₂ g

|

||

Aggregate impact value

= (W₂/W₁) ⨉ 100 %

|

Calculations:-

Formula for Aggregate Impact Value Test:

Result:-

Aggregate Impact Value = ………. %

Recommended

Values of Aggregate Impact Test:-

Classification

of aggregates using Aggregate Impact Value is as given below:

Aggregate Impact Value

|

Classification

|

<20%

|

Exceptionally

Strong

|

10 – 20%

|

Strong

|

20-30%

|

Satisfactory

for road surfacing

|

>35%

|

Weak for road surfacing

|

Specified

limits of percent aggregate impact value for different types of road

construction by Indian Roads Congress are given below:

Sl. No.

|

Type

of Pavement

|

Aggregate

Impact Value Should Not More Than

|

1.

|

Wearing Course

|

30

|

a)

|

Bituminous

surface dressing

|

|

b)

|

Penetration macadam

|

|

c)

|

Bituminous

carpet concrete

|

|

d)

|

Cement concrete

|

|

2.

|

Bitumen

bound macadam base course

|

35

|

3.

|

WBM base course with bitumen surfacing

|

40

|

4.

|

Cement

concrete base course

|

45

|

thanks, this was so helpful.

ReplyDeleteThanks for your help

ReplyDelete