Aggregate crushing value is one of the

major mechanical properties required in a road stone. The aggregate crushing value provides a relative measure

of the resistance of sample aggregate to crushing

under a gradually applied compressive load.

Crushing value is a measure

of the (crushing) strength of the aggregate. Therefore, the aggregates

should have minimum crushing value. The aggregates possessing low aggregate crushing value

should be preferred to achieve a high quality of pavement.

The aggregate crushing value test is an

important test of aggregates. It gives a numerical index of the strength of

the aggregate and it is used for concrete in construction of

roads and pavements.

The aggregates, have

minimum crushing value, are recommended for roads and pavements as it indicates

a lower crushed fraction under load and would give a longer service life and a

more economical performance.

The aggregate crushing value is calculated,

as a ratio of the weight of fines aggregate passing through the specified IS

sieve to the total weight of the aggregate sample and is expressed as a

percentage. Where, W₁ = Total weight

of dry sample and W₂ = Weight of

the portion of crushed material passing through 2.36 mm IS

sieve.

The aggregates used

in construction of roads and pavements must be strong enough to withstand

crushing under roller and traffic. If the aggregate crushing value is obtained 30 or higher, the result may be anomalous and in such

cases the ten percent fines value should be determined instead.

The crushing strength or aggregate crushing value of a

given road aggregate (stone) is obtained as per IS-2386 Part- 4.

AGGREGATE CRUSHING VALUE TEST, CRUSHING VALUE TEST OF AGGREGATE, IS 2386 (PART-4)-1963

Hi friends, you are welcomed in the world of Civil Allied Gyan. Here I have explained about crushing value test of road

aggregate. Read definition, apparatus, IS code, procedure, observations,

formula, result, lab report about aggregate crushing value test of coarse aggregate. Save in pdf.

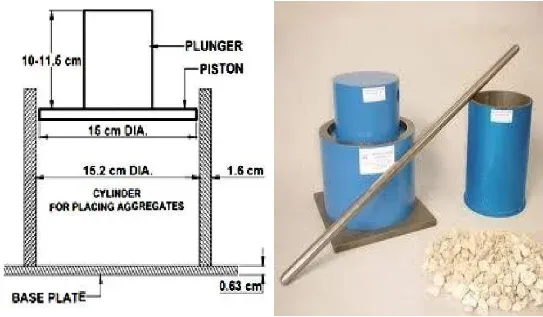

- An open-ended steel cylinder of 15 cm diameter with plunger and base plate.

- A straight metal tamping rod of circular cross-section 16 mm in diameter, 45 cm to 60 cm in length and rounded at one end.

- A balance of capacity 3 kg and accurate to 1 g.

- Oven

- Dial gauge

- IS sieves of sizes 12.5 mm, 10 mm and 2.36 mm.

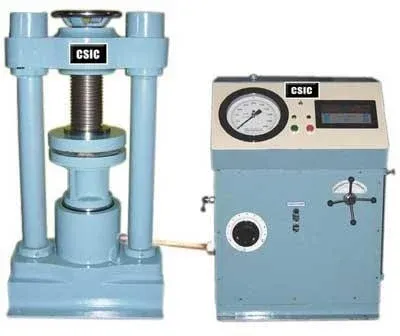

- A compression-testing machine capable of applying compressive load up to 40 tons.

- Cylindrical measure having internal diameter of 11.5 cm and height 18 cm for measuring the sample.

- IS: 2386 (Part 4) -1963, Methods of test for aggregate for concrete

- IS: 383: 1970, Specification of coarse aggregate and fine aggregate from natural source for concrete

- IS: 9376: 1979, Specification of apparatus for measuring crushing value of aggregate

Procedure of Aggregate

Crushing Value Test:-

- Sieve the test material through 12.5 mm and 10.0 mm IS sieve.

- Take test samples of aggregates passing through

12.5 mm IS sieve and retained on 10 mm IS sieve (minimum 3 Kg).

- Dry theme in an oven for 4 hours at a temperature of 100 °C to 110 °C and then cool at room temperature.

- Put the cylinder of the test in position on the base-plate.

- Fill the aggregates up to about 1/3 full in the cylindrical measure and tamp for 25 times with rounded end of the tamping rod.

- Fill the rest portion of the cylindrical measure by two layers (1/3 + 1/3) and tamp each layer for 25 times.

- Cut off the overflow of aggregates in

cylindrically measure by tamping rod using its straight edge or by a knife for

level the surface of the aggregates.

- Then weigh the entire aggregates sample of the measuring cylinder with an accuracy to 0.01 g.

- Insert the plunger so that it rests horizontally on this surface and take care to ensure that the plunger does not jam in the cylinder.

- Then place the apparatus, with the test sample and plunger in position, between the plates of the testing machine.

- Apply the load at a uniform rate as possible so that the total load will reach 40 tons in 10 minutes.

- Release the load and remove the whole of the material from the cylinder and sieve on 2.36 mm IS sieve.

- Weigh and record the fraction passing through the 2.36 mm IS sieve.

Observations:-

Table: Crushing

value of sample aggregates

Observations

|

Trail No. 1

|

Trail No. 2

|

Total weight of dry sample taken = W₁ g

|

||

Weight of aggregate passing through 2.36 mm sieve = W₂ g

|

||

Aggregate crushing value = (W₂/W₁)×100%

|

Calculations:-

Formula

for Aggregate Crushing Value Test:

Where,

W₁ = Total weight of dry sample and

W₂ = Weight of the portion of crushed material passing through 2.36 mm IS

sieve.

Result:-

Aggregate Crushing Value =………… %

Report:-

The average value of the two results is

reported to the nearest whole number as the aggregate crushing value of the

tested material.

Safety and Precautions While Testing:

- Before testing, check the testing machine.

- Wear safety shoes and helmet during the test.

- After drying the materials, switch off the oven and wear hand gloves while removing containers from oven.

- Keep all the exposed metal parts greased.

- Keep the guide rods firmly fixed to the base and top plate.

- Clean the equipment thoroughly before testing and after testing.

- After test, clean the sieve by brush and switch off electric supply.

|

| Compression Testing Machine |

The aggregate crushing value test evaluates the ability of the aggregates used in road or

pavement construction to withstand the stresses induced by moving vehicles in

the form of crushing. With this, the aggregates should also provide sufficient

resistance to crushing under the roller during construction work and under

rigid tyre rims of heavily loaded animals or men drawn vehicles.

Limits of

Aggregate Crushing Value of the Coarse Aggregates:-

According to Indian Standard (IS) and Indian Road

Congress (IRC), the aggregate crushing value of the coarse aggregates used for ‘cement

concrete pavement’ at surface should not exceed 30% and aggregates used for

concrete other than for wearing surfaces, should not exceed 45%.

Aggregate

Crushing Values for Roads and Pavement Construction

The

table below shows specified limits of aggregate crushing value for different

types of road construction by Indian Roads Congress:

Types of Roads / Pavements

|

Aggregate Crushing Value Limit (%)

|

Flexible Pavements

|

|

Soling

|

50

|

Water bound macadam

|

40

|

Bituminous macadam

|

40

|

Bituminous surface dressing or thin premix carpet

|

30

|

Dense mix carpet

|

30

|

Rigid Pavements

|

|

Other than wearing course

|

45

|

Surface or Wearing course

|

30

|

Read More: