AGGREGATE ABRASION VALUE TEST | LOS ANGELES ABRASION VALUE TEST OF AGGREGATE

Hi friends, you are welcomed in the Civil

Allied Gyan. In this article I have explained about abrasion value test of coarse aggregates.

Why we test abrasion value of coarse aggregates ?

The abrasion value of the aggregates is

determined in order to determine their Resistance against wearing. In this the

aggregate sample is mixed with abrasive charge consisting standard balls &

rotated in closed inclined cylinders for specific number of revolutions.

APPARATUS

REQUIRED FOR THE TEST:-

- Los Angeles Machine:- It consists of a hollow steel cylinder, closed at both the ends with an internal diameter of 700 mm and length 500 mm and capable of rotating about its horizontal axis.

- Cast iron or steel balls, approximately 48 mm in diameter and each weighing between 390g to 445 g; 6 to 12 balls are required.

- IS sieve

- Balance

IS code for aggregate abrasion value test :-

- IS: 2386 (Part IV) – 1963

- IS: 383-1970

PROCEDURE

OF THE TEST:-

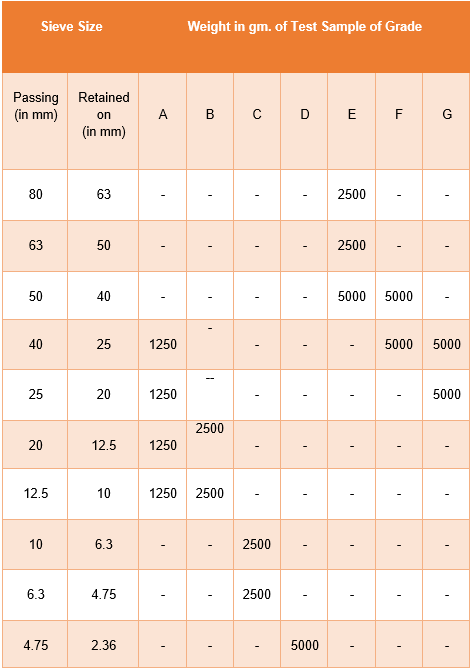

- The test sample shall consist of clean aggregate which has been dried in an oven at 105 °C to 110 °C to substantially constant weight and shall conform to one of the grading shown in Table.

- The grading or grading used shall be those most nearly representing the aggregate furnished for the work.

- The test sample and the abrasive charge shall be placed in the Los Angeles abrasion testing machine and the machine rotated at a speed of 20 to 33 rev/min.

- For grading A, B, C and D, the machine shall be rotated for 500 revolutions; for grading E, F and G, it shall be rotated for 1000 revolutions.

- The machine shall be so driven and so counter-balanced as to maintain a substantially uniform peripheral speed.

- If an angle is used as the shelf, the machine shall be rotated in such a direction that the charge is caught on the outside surface of the angle.

- At the completion of the test, the material shall be discharged from the machine and a preliminary separation of the sample made on a sieve coarser than the 1.70 mm IS sieve.

- The material coarser than the 1.70 mm IS Sieve shall be washed dried in an oven at 105 °C to 110°C to a substantially constant weight, and accurately weighed to the nearest gram.

TABULAR

COLUMN :-

Table:- Specified Abrasive Charge

Grading

|

Number of Spheres

|

Weight of Charge (g)

|

A

|

12

|

5000 土 25

|

B

|

11

|

4584 土 25

|

C

|

8

|

3330 土 20

|

D

|

6

|

2500 土 15

|

E

|

12

|

5000 土 25

|

F

|

12

|

5000 土 25

|

G

|

12

|

5000 土 25

|

Table:- Gradings of Test Samples

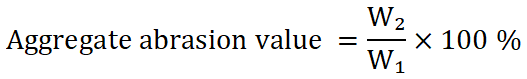

OBSERVATIONS :-

Table:-

Trail

1

|

Trail

2

|

|

Total weight of dry sample taken= W1

g

|

||

Weight of portion passing 1.7 mm sieve=

W2 g

|

||

Aggregate abrasion

value = (W2/W1) x 100(%)

|