Angularity number test gives us an idea of how angular

the aggregate is. This is based on the percentage of voids in the aggregate

after compacting in a specified manner.

Angularity is the absence of roundness in aggregates. A more

rounded aggregate particle has less angularity and vice versa.

Angularity number of aggregate is the amount

(a whole number) by which the percentage of volume of voids in it after compaction

in a prescribed method exceeds 33. Where “33” is the percentage of volume of

voids in a perfectly rounded aggregate.

Angularity number test is

conducted on coarse aggregates sample to estimate the shape of aggregates.

This test helps us to determine the angularity number of the coarse

aggregate. Higher angularity number aggregates are better in interlocking. The angularity

number of coarse aggregate along with flaky index and elongation index helps us

to prepare bituminous mixes that would give satisfactory performance.

Angularity Number Test for Coarse Aggregate, Shape Test for Aggregate, IS: 2386 (Part 1)–1963

Hi friends, you are welcomed in the world of Civil Allied Gyan. Here, I have

explained about angularity number test for coarse aggregate.

By the help of this you can easily find the angularity

number of coarse aggregate. So please continue to the end & keep your love

and support on me.

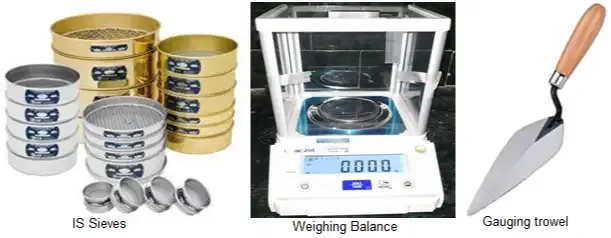

- Metal cylinder

- Tamping rod

- Balance

- Gauging trowel

- Sieves (20, 16, 12.5, 10, 6.3 and 4.75mm)

- Metal scoop

- IS: 2386 (Part 1)–1963, Method of test of aggregates for formation of concrete

- IS: 383–1970, Specification for coarse and fine aggregate from natural source for formation of concrete

Description of

Angularity Number Test for Coarse Aggregate:-

First the metal mould calibrated by filling it with water

and determining the weight of water in it. Then the mould is filled with clean

dried aggregates samples in three layers. The weight of aggregate specimens in

the mould is recorded. Determine the specific gravity of the aggregate. Finally

the angularity number of aggregate is calculated.

Preparation of

Test Sample:-

The test samples consist of aggregates passes through and

retained on between the appropriate pairs of IS sieves from the following sets

given in Table 1.

Table 1:

Passing

Through IS Sieves

|

Retained On

IS Sieves

|

20 mm

|

16 mm

|

16 mm

|

12.5 mm

|

12.5 mm

|

10 mm

|

10 mm

|

6.3 mm

|

6.3 mm

|

4.75 mm

|

The aggregate sample to be tested should be dried for at least 24 hours in a well ventilated oven maintained at a temperature of 100 ºC to 110 ºC.

Procedure of Angularity Number Test for Coarse Aggregate:-

- Sieve the aggregate sample with sieves specified in Table 1.

- Fill the metal cylinder with water and record its volume.

- Take sufficient quantity of aggregate to perform the test.

- Compact the aggregate in three layers, each layer being given 100 blows (strokes) using the standard tamping rod at a rate of 2 blows/second by lifting the rod 5 cm over the surface of the aggregate and then allowing it to fall freely.

- The blows (strokes) should be uniformly distributed over the surface of the aggregate.

- After compacting the third layer, fill the cylinder to overflowing and remove off the excess material with temping rod as a straight edge.

- Then weigh the aggregate (water and aggregate) with cylinder.

- Make three separate determinations and calculate the average weight of the aggregates in the cylinder.

Observation and Calculation:-

Table 2: Percentage of voids in aggregate samples

Descriptions

|

Trail No. 1

|

Trail No. 2

|

Volume of metal measures, V₁ (ml)

|

||

Volume of water required to fill the metal measures containing

aggregate, V₂

(ml)

|

||

Percentage of voids, (V₂/V₁) ⨉ 100%

|

Formula

for percentage of voids:

Formula

for angularity number of aggregate:

Angularity

number of aggregate = V-33 = ................

Where,

W = Average weight of the aggregate filling

cylinder,

C = Weight of water required to completely

fill the cylinder and

Gs =

Specific Gravity of the aggregate.

Result:-

Angularity number of aggregate =……………

Report:-

The average value of three determinations,

expressed to the nearest whole number, is reported.

Safety and Precautions to the Test:-

- Use safety shoes, mask and aprons at the time of test.

- Thoroughly clean and dry the container before testing.

- All parts of the equipment, used in the test, should always be kept clean.

- Specially care that no outer air should be entered when using the weighing balance.

- After the test has done, sieve should be clean by a soft brush.

Read also:-

Good 👍

ReplyDelete