What is bulk density?

The bulk density is

the weight of material in a given volume. It is measured in kilograms per miter

cube but for the purpose of this standard it is measured in kilograms per

litre.

Who

affects bulk density of sand?

The bulk density of sand

is affected by several factors, including the amount of moisture present and

the amount of effort introduced in filling the measures.

What

is bulking of sand?

The increase in

volume of sand (or aggregate) due to presence of moisture is known as bulking

of sand.

What

is bulking factor?

The bulking factor is

defined as the ratio of the volume of moist sand to volume of the sand when

dry.

Necessary Adjustment for Bulking of Fine Aggregate by Field Method

Hi friends, you are

welcomed in the world of Civil Allied Gyan. “Read definition, apparatus,

IS code, procedure, formula, result and lab report for necessary adjustment for

bulking of fine aggregate by field method.”

IS Code for Determination of Necessary Adjustment for Bulking of Fine Aggregate:-

IS: 2386-3 (1963); Methods for specific gravity, density, voids, absorption and bulking

of aggregates.

Apparatus

Required for Determination of Necessary

Adjustment for Bulking of Fine Aggregate:-

- A Balance sensitive to 0.5 %

- Special Vessel for unit volume

- Tray

- Steel Rod

- Cylindrical Metal Containers

- Hot Air Oven

Procedure for Determination of Bulk Density and Voids in Aggregate:-

The procedure to be adopted may be varied, but three methods are

suggested below. The first two method depend on the fact that the volume of inundated

sand is the same as if the sand were dry.

Method-1

- Put sufficient quantity of the sand loosely into a container. Until it is about two thirds full.

- Level off the top of the sand and pushing a steel rule vertically down

through the sand at the middle to the bottom, measure the height. Suppose that

this is h₁ cm.

- Empty the sand out of the container into another container where none of it will be lost.

- Half fill the first container with water.

- Put back about half the sand and rod it with a steel rod, about 6 mm in diameter, so that its volume is reduced to a minimum.

- Then add the remainder of the sand and rod it in the same way.

- Smooth and level the top surface of the inundated sand and measure its

depth at the middle with the steel rule. Suppose that this is h₂ cm.

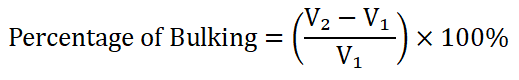

Calculation:-

The percentage of bulking of the sand due to moisture shall be calculated

from the formula given below.

Method-2

- In a 250 ml measuring cylinder, pour the damp sand (consolidated by shaking) until it reaches the 200 ml mark.

- Then fill the cylinder with water and stir the sand well.

- The water shall be sufficient to submerge the sand completely.

- It will be seen that the sand surface is now below its original level. Suppose the surface is at the mark y ml.

Calculation:-

The percentage of bulking of the sand due to moisture shall be calculated

from the formula given below.

Method-3

- Take about 200 g of

dry sand in a 1 liter jar and find its volume (V₁)

- Put the above sand in a mixture pan and add 2% water by weight. Mix it thoroughly to get uniform color.

- Fill this moist sand

into the 1 liter cylinder and note down the volume (V₂).

Calculation:-

The increase in

volume = V₂−V₁

Bulking factor = V₂/V₁

Repeat the experiment with different

percentages of water i.e. 4, 6, 8, 12, 16%.

Plot the graph of bulking factor on Y-axis v/s

moisture content by percentage of dry mass of sand on X-axis. This is known as

bulking curve.

Observations:-

Reporting

of Results:-

Report the bulking percentage of the sand to

the nearest whole number.

Significance of field test to find out the percentage of bulking of fine aggregate:-

The field test to find out the percentage of

bulking is so simple that this could be conducted in a very short time interval

and the percentage of bulking so found out could be employed for correcting the

volume of fine aggregate to be used. This can be considered as one of the

important methods of field control to produce quality concrete. Since volume

batching is not adopted for controlled concrete, the determination of the moisture

content percentage is not normally required. The quality of water could be

controlled by visual examination of the mixture and by experience. The

percentage free moisture content is required to be determined and correction

made only when weigh batching is adopted for production of quality concrete.

|

Thanks for reading this article. Please, don’t forget

to share it. |