What is bulk density?

The bulk density is

the weight of material in a given volume. It is measured in kilograms per miter

cube but for the purpose of this standard it is measured in kilograms per

litre.

Who

affects bulk density of aggregate?

The bulk density of

an aggregate is affected by several factors, including the amount of moisture

present and the amount of effort introduced in filling the measures.

What

is bulking of sand?

The increase in

volume of sand (or aggregate) due to presence of moisture is known as bulking

of sand.

What

is the reason behind bulking of sand?

The bulking of sand

is due to the formation of thin film of water around the sand grains and the

interlocking of air in between the sand grains and the film of water.

When more water is

added a sand particle got submerged and volume again becomes equal to dry

volume of sand. To compensate the bulking effect extra sand is added in the

concrete so that the ration of coarse to fine aggregate will not change from

the specified value. Fine sand shows greater percentage of bulking than coarse

sand with equal percentage of moisture.

Bulk Density and Voids in Aggregate asper IS: 2386-3 (1963)

Hi friends, you are

welcomed in the world of Civil Allied Gyan. “Read here definition, apparatus,

IS code, test procedure, formula, result and lab report for bulk density and voids in aggregate as per

IS: 2386-3 (1963).”

Important:- This

method of test covers the procedure for determining unit weight or bulk density

and void of aggregates.

Note-1: It

is emphasized that this is a laboratory test intended for comparing properties

of different aggregates. It is not generally suitable for use as a basis for quoting

mix design conversion factors.

Note-2:

Considerably

more compactive effort is used in the determination of angularity number [as

per IS: 2336 (Part 1)-1963] than in this test, and hence the values for bulk

density and voids are different.

IS Code of Bulk Density and Voids in Aggregate:-

IS: 2386 (Part 3)-1963, Methods for specific gravity, density, voids, absorption and bulking

of aggregates.

Apparatus

Required for Determination of Bulk

Density and Voids in Aggregate:-

- Balance: A balance sensitive to 0.5 % of the weight of the given sample.

- Tamping Rod: A straight metal tamping rod of cylindrical cross-section 16 mm in diameter and 60 cm long and rounded at one end.

- Special Vessel for unit volume

- Tray

- Cylindrical Metal Containers: See below table.

Table-1: Size of Container for Bulk Density Test

Calibration:- The measure shall be calibrated by determining the weight of water at 27°C required to fill it such that no meniscus is present above the rim of the container. The capacity in litres shall be obtained by dividing the weight of water in kilograms required to fill the container at 27°C by the weight of water in 1 litre at 27°C, which may be taken as 1 kg.

Procedure for Determination of Bulk Density and Voids in Aggregate:-

- Condition

of Specimen:- For the determination of the voids the dry

material may normally be used, but

when bulking tests are required, then the material with a given percentage of

moisture may be used.

- Take the appropriate

container and weight it (M₁).

- Then fill the cylindrical metal container about one-third full with thoroughly mixed aggregate and tamped with 25 strokes of the rounded end of the tamping rod.

- Add further similar quantity (one-third of measure) of aggregate and tamped with 25 strokes of the rounded end of the tamping rod again.

- Finally fill the measure to over-flowing, tamped with 25 times of the rounded end of the tamping rod again and struck off the surplus aggregate using the tamping rod as a straightedge.

- Then weight the

container with sample (M₂)

and determine the net weight of the aggregate in the measure (M₂−M₁), which is called rodded or

compacted weight.

- Calculate the bulk density of sample aggregate in kilograms per litre (the formula is given below in calculations).

- Now fill the measure to over-flowing by means of a shovel or scoop, discharge the aggregate from a height not exceeding 5 cm above the top of the measure.

- Care shall be taken to prevent, as far as possible, segregation of the particle sizes of which the sample is composed.

- Level the surface of the aggregate using the tamping rod as a straightedge.

- Then weight the

container with sample (M₃)

and determine the net weight of the aggregate in the measure (M₃−M₁), which is called loose

weight.

- Calculate the bulk density of sample aggregate in kilograms per litre (the formula is given below in calculations).

Calculations:-

Calculation of Bulk Density: The bulk density of aggregate will be calculated as follows:

Where;

M₁ = Weight of container in kg,

M₂ = Weight of container and sample in kg,

M₃ = Weight of container and sample in kg,

V = Volume of container

in L,

Compacted weight = M₂−M₁ and

Loose weight = M₃−M₁.

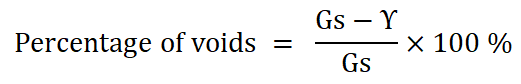

Calculation

of Voids: The percentage of voids will be calculated as follows:

Where,

Gs = Specific

gravity of the aggregate, and

Υ = Bulk density in kg/litre.

Reporting of Results:–

The bulk density of

aggregate will be reported in kg/litre to the nearest 0.01 kg/L.

The voids in aggregate

will be reported as a percentage to the nearest whole number.

The condition of sample

aggregate at the time of test shall be stated, that is (a) oven dry, (b)

saturated and surface dry, or (c) with a given percentage of moisture.

|

Thanks for reading this article. Please, don’t forget

to share it. |