What is California Bearing Ratio (CBR) of Soil?

The following table gives

the standard loads adopted for different penetrations for the standard material

with a CBR value of 100%.

|

Penetration of Plunger |

Standard Load |

|

2.5 mm |

1370 kg |

|

5.0 mm |

2055 kg |

Note:- For

Railway Formation purpose, the test is performed on remoulded specimens which

are compacted dynamically.

What

is California Bearing Ratio Test (CBR Test) of Soil?

|

California Bearing Ratio Test Procedure, CBR Test of Soil as per IS: 2720 (Part 16): 1987

Hi friends, you are welcomed in the world

of Civil

Allied Gyan. “Read here definition, apparatus, IS code, procedure, formula and lab

report about California Bearing

Ratio test procedure i.e. CBR test of soil.”

IS Code for California Bearing Ratio (CBR) Test of Soil:-

IS: 2720 (Part 16): 1987; Methods of test for

soils: Determination of California Bearing Ratio (second revision) of soil.

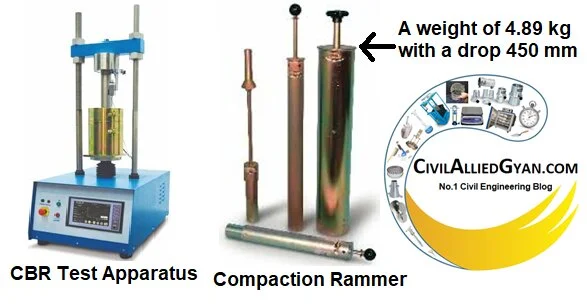

CBR Test Apparatus List

|

Apparatus |

Specification |

|

CBR

Moulds |

With

Base Plate, Stay Rod and Wing Nut |

|

Cylindrical

mould |

Inside

diameter 150 mm and height 175 mm with a detachable perforated base plate of

235 mm diameter and 10mm thickness. Net capacity will be 2250 ml; conforming

to IS-9669: 1980 |

|

Collar |

A

detachable extension collar of 60 mm height |

|

Spacer

Disc |

148

mm in diameter and 47.7 mm in height along with handle |

|

Metal

Rammer |

Weight

4.89 kg with a drop 450 mm; for compaction |

|

Expansion

Measuring Apparatus |

The

adjustable stem with perforated plates and tripod |

|

Weights |

One

annular metal weight and several slotted weights weighing 2.5 kg each, 147 mm

in dia., with a central hole 53 mm in dia. |

|

Loading

Machine |

With

a capacity of at least 5000kg and equipped with a movable head or base which

enables the plunger into penetrate into the specimen at a deformation rate of

1.25 mm/min. |

|

Penetration

Plunger |

Metal

penetration piston 50 mm diameter and minimum of 100 mm in length (conforming

to IS: 9669-1980) |

|

Dial

Gauges |

Two

dial gauges sensitive to 0.01 mm |

|

Sieves |

47.5

mm and 19 mm IS Sieves |

|

Other

apparatus Mixing bowl, scales, straightedge,

drying oven, filter paper, soaking tank or pan, dishes and calibrated

measuring jar |

|

|

Procedure for California Bearing Ratio Test (CBR Test) of Soil:-

1. Preparation of Specimens:

The CBR test of soil may be performed on undisturbed specimens or remoulded specimens which may be compacted either statically or dynamically.

Note: The

static method of compaction gives the required density but requires

considerable pressure and there is a possibility of the actual density varying

with depth though the average density may be the one desired.

Undisturbed Specimen: Undisturbed

specimen will be obtained by fitting to the mould, the steel cutting edge of

150 mm internal diameter and pushing the mould as gently as possible into the

ground and digging away the soil as the mould is pushed in. When the mould is sufficiently

full of soil, it will be removed by under digging, the top and bottom surface

are then carefully trimmed flat so as to give the required length of specimen

ready for testing. The density of the soil will be determined.

Remoulded Specimens: The

dry density for a remoulding will be either the field density or the value of

the maximum dry density estimated by the compaction tests.

Note: For

Railway Formation, dry density is estimated by heavy compaction test as per IS:

2720: Part-8: 1983.

The water content used for compaction should

be the optimum water content or the field moisture as the case may be.

Soil

Sample: The

test material (i.e. soil) used in the remoulded specimen should pass 19 mm IS

sieve and retained on 4.75 mm IS sieve.

Statically Compacted Specimens: The

mass of the wet soil at the required water content to give the desired density

when occupying the standard specimen volume in the mould will be calculated. A

batch of soil will be thoroughly mixed with water to give the required water

content. The correct mass of the moist soils will be placed in the mould and compaction

obtained by pressing in the displacer disc, a filter paper being placed between

the disc and the soil.

Dynamically Compacted Specimens: For

dynamic compaction, a representative sample of the soil weighing approximately 4.5

kg or more for fine-grained soil and 5.5 kg or more for granular soil will be

taken and mixed thoroughly with water. If the soil is to be compacted to the

maximum dry density at the optimum moisture content, the exact mass of the soil

required will be taken and the necessary quantity of water added so that the

water content of the soil sample is equal to the determined optimum moisture

content.

Next steps:-

- The mould with the extension collar attached shall be clamped to the base plate and the spacer disc is inserted over the base plate.

- A disc of coarse filter paper placed on the top of the spacer disc.

- Lubricating oil is applied to the inner side of the mould.

- The soil-water mixture shall be compacted into the mould using heavy compaction. i.e. the soil is compacted in 5 layers with 55 blows to each layer by the 4.89 kg rammer.

- The extension collar shall then be removed and the compacted soil carefully trimmed even with the top of the mould by means of a straightedge.

- Any holes developed on the surface of the compacted soil by removal of the coarse material, shall be patched with the smaller size material.

- The perforated base plate, the spacer disc and filter paper shall be removed and the mass of the mould and the compacted soil specimen shall be recorded.

- A disc of coarse filter paper shall be placed on the perforated base plate, the mould and the compacted soil shall be inverted and the perforated base plate clamped to the mould with the compacted soil in contact with the filter paper.

- In both cases of compaction, if the sample is to be soaked, representative samples of the material at the beginning of compaction and another sample of the remaining material after compaction shall be taken for determination of water content. Each water content sample shall weigh not less than about 50 g.

- If the sample is not to be soaked, a representative sample of material from one of the cut-pieces of the material after penetration shall be taken to determine the water content. In all cases, the water content shall be determined in accordance with IS: 2720 Part-2.

2. Procedure for Swelling Test:-

- A filter paper shall be placed over the specimen and the adjustable stem and perforated plate shall be placed on the compacted soil specimen in the mould.

- Weights to produce a surcharge equal to the weight of base material and pavement to the nearest 2.5 kg shall be placed on the compact soil specimen.

- The whole mould and weights shall be immersed in a water tank allowing free access of water to the top and bottom of the specimen.

- The tripod for the expansion measuring device shall be mounted on the edge of the mould and the initial dial gauge reading recorded.

- This set-up shall be kept undisturbed for 96 hours noting down the readings every day against the time of reading.

- A constant water level shall be maintained in the tank throughout the period.

- At the end of the soaking period, the change in dial gauge shall be noted, the tripod removed and the mould taken out of the water tank.

- The free water collected in the mould shall be removed and the specimen allowed draining downwards for 15 minutes and care shall be taken not to disturb the surface of the specimen during the removal of the water.

- The weights, the perforated plate and the top filter paper shall be removed and the mould with the soaked soil sample shall be weighed and the mass recorded.

3. Procedure for Penetration Test:-

- The mould containing the specimen, with the base plate in position but the top face exposed, shall be placed on the lower plate of the penetration testing machine.

- To prevent upheaval of soil into the hole of the surcharge weights, 2.5 kg annular weight shall be placed on the soil surface prior to seating the penetration plunger after which the remainder of the surcharge weights shall be placed.

- The plunger shall be seated under a load of 4 kg so that full contact is established between the surface of the specimen and the plunger.

- The load and deformation gauges shall then be set to zero and load is applied to the plunger into the soil at the rate of 1.25 mm per minute.

- Reading of the load is taken at penetrations of 0.5, 1.0, 1.5, 2.0, 2.5, 4.0, 5.0, 7.5, 10.0 mm and 12.5 mm.

- The plunger shall be raised and the mould detached from the loading equipment.

- About 20g to 50g of soil shall be collected from the top 30mm layer of the specimen and the water content determined.

Observations and Recording:-

Recordings during CBR Test

|

Penetration (in mm) |

Applied Load (in kg) |

|

0.50 |

|

|

1.00 |

|

|

1.50 |

|

|

2.00 |

|

|

2.50 |

|

|

4.00 |

|

|

5.00 |

|

|

7.50 |

|

|

10.00 |

|

|

12.50 |

|

Calculations:-

Formula for California

Bearing Ratio Test (CBR Test) of soil:-

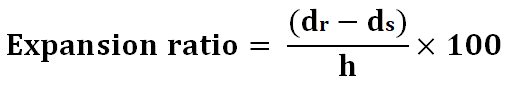

a)

Where,

dr = final

dial gauge reading in mm,

ds = initial

dial gauge reading in mm and

h =

initial height of the specimen in mm.

b)

Where,

PT = corrected unit (or total) test

load corresponding to the chosen penetration from the load penetration curve,

and

Ps = unit (or total) standard load

for the same depth of penetration as for PT taken.

Lab Report:-

The results of the California Bearing Ratio (CBR)

test of soil are presented as the CBR value and the expansion ratio.

CBR of specimen at 2.5 mm penetration = ............

Note:- The

CBR values are usually calculated for penetration of 2.5 mm and 5 mm. Generally

the CBR value at 2.5 mm will be greater than at 5 mm and in such a case/the

former will be taken as CBR for design purpose. If CBR for 5 mm exceeds that

for 2.5 mm, the test should be repeated. If identical results follow, the CBR

corresponding to 5 mm penetration should be taken for design.

Load Penetration Curve:-

The load penetration curve will be plotted (see below Fig.). This curve is usually convex upwards although the initial portion of the curve may be convex downwards due to surface irregularities. A correction will then be applied by drawing a tangent to the point of greatest slope and then transposing the axis of the load so that zero penetration is taken as the point where the tangent cuts the axis of penetration. The corrected load-penetration curve would then consist of the tangent from the new origin to the point of tangency on the re-sited curve and then the curve itself, as illustrated in below Fig.

|

| Graph between Load versus Penetration. |

|

Penetration Depth |

Unit Standard Load |

Total Standard Load |

|

(1) |

(2) |

(3) |

|

mm |

kg/cm² |

kgf |

|

2∙5 |

70 |

1370 |

|

5∙0 |

105 |

2055 |

If the initial portion of the curve is

concave upwards, apply correction by drawing a tangent to the curve at the

point of greatest slope and shift the origin. Find and record the correct load

reading corresponding to each penetration.

|

Thanks for reading this article.

Please, don’t forget to share it. |

Very informative.

ReplyDelete