What is Lightweight Pieces Test in Aggregate?

The lightweight pieces test in aggregate covers

the procedure for determination of approximate percentage of light-weight

pieces in aggregate by means of sink-float separation in a heavy liquid of

suitable specific gravity.

Determination of Lightweight Pieces (Coal and Lignite) in Aggregate

Hi friends, you are welcomed in the world

of Civil Allied Gyan. Here I

have explained about determination of lightweight pieces (coal and lignite) in

aggregate. “Read definition, apparatus, IS code, procedure,

formula, result, lab report about determination

of lightweight pieces (coal and lignite) in aggregate.”

IS

Code for Determination of Lightweight Pieces (Coal and Lignite) in Aggregate:-

IS: 2386 (Part-2) 1963, Method of estimation

of deleterious materials and organic impurities.

Apparatus Required for Determination of Lightweight Pieces (Coal and Lignite) in Aggregate:-

- Heavy Liquid

- Balance: For weighing the aggregate not less than 500g capacity (0.1g at least count) and for coarse aggregate not less than 5000g capacity (1.0g at least count).

- Containers: First container suitable for drying the aggregate sample and second container suitable for holding the heavy liquid during the sink-float separation.

- Skimmer: A piece of 300-micron sieve cloth of suitable size and shape for separating the floating pieces from the heavy liquid.

- Hot Plate or Oven

- IS Sieves: 4.75 mm and 300 micron sieves

Specification for Heavy Liquid:-

The heavy liquid shall consist of a mixture

of carbon tetrachloride and 1,1,2,2 tetrabromoethane, bromoform and monobromobenzene

or bromoform and benzene in such proportions that the desired specific gravity

will be obtained. Bromotrichloromethane

may be used as a heavy liquid having a specific gravity of 2.00. The

specific gravity shall be maintained within ± 0.01 of the specified value at

all times during the test.

The approximate volumes of materials to be

combined to produce a mixture of the desired specific gravity may be computed

from the following specific gravities of the different liquids:

|

Heavy Liquid |

Specific

Gravity |

|

1,1,2,2-tetrabromoethane |

2.97 |

|

Benzene |

0.88 |

|

Bromoform |

2.88 |

|

Carbon tetrachloride |

1.58 |

|

Monobromobenzene |

1.49 |

Sampling of the test specimen:-

The minimum size of test sample will be as follows:-

|

Maximum size of aggregate (in mm) |

Minimum weight of sample (in g) |

|

6.3 (Fine

aggregate) |

6.3 (Fine

aggregate) 200 |

|

20 |

3000 |

|

40 |

5000 |

|

80 |

10000 |

Procedure for

Determination of Lightweight Pieces (Coal and Lignite) in Aggregate:-

(A) For

Fine Aggregate

- Dry the sample (fine aggregate) and cool to room temperature.

- Sieve the sample over a 300-micron IS sieve until less than one percent of the retained material passes the sieve in one minute of continuous sieving.

- Weigh the material coarser than the 300-micron IS Sieve to the nearest 0.1g.

- Place the sample in a container and mix the heavy liquid, the volume of heavy liquid being at least three times the absolute volume of the aggregate sample.

- Pour the liquid off into a second container, passing it through the skimmer and taking care that only the floating pieces are purred off with the liquid and that none of the sand is decanted onto the skimmer.

- Return to the first container, the liquid that has been collected in the second container and, after further agitation of the sample by stirring, repeat the decanting process just described until tile sample is free of floating pieces.

- Wash the decanted pieces contained on the skimmer in carbon tetrachloride, until the heavy liquid is removed.

- The pieces will dry very quickly, but may be placed in an oven at 105 ºC for a few minutes if desired.

- Brush the dry decanted piece from the skimmer onto the balance pan and determine the weight to the nearest 0.1g.

- Note- Brownish

black or black materials shall be considered as coal and lignite and shall be

collected and weighed to the nearest 0.1g.

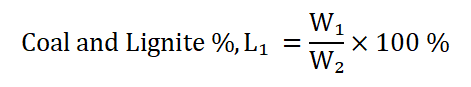

Calculations:-

Calculate the percentage of light-weight pieces (pieces floating on the heavy liquid) in fine aggregate as follows:

Where,

L₁ = Percentage of light-weight pieces;

W₁ = Weight

of dry sample of decanted piece in g; and

W₂ = Weight

of portion of dry sample in g (coarser than 300-micron IS Sieve).

(B) For

Coarse Aggregate

- Dry the sample (coarse aggregate) and cool to room temperature.

- Sieve the sample over a 4.75-mm IS sieve until less than one percent of the retained material passes the sieve in one minute of continuous sieving.

- Weigh the material coarser than the 4.75-mm IS Sieve to the nearest 1g.

- Place the sample in a container and mix the heavy liquid, the volume of heavy liquid being at least three times the absolute volume of the aggregate sample.

- Using the skimmer, remove the floating pieces that rise to the surface, and save them.

- Repeatedly agitate the remaining pieces and remove the floating pieces until no additional pieces rise to the surface.

- Wash the decanted pieces contained on the skimmer in carbon tetrachloride, until the heavy liquid is removed.

- The pieces will dry very quickly.

- Brush the dry decanted piece from the skimmer onto the balance pan and determine the weight to the nearest 1g.

- Note- Brownish

black or black materials shall be considered as coal and lignite and shall be

collected and weighed to the nearest 1g.

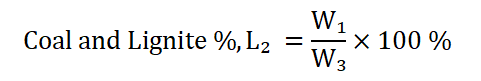

Calculations:-

Calculate the percentage of light-weight pieces (pieces floating on the heavy liquid) in coarse aggregate as follows:

Where,

L₂ = Percentage of light-weight pieces;

W₁ = Weight

of dry sample of decanted piece in g; and

W₃ = Weight of portion of dry sample in g

(coarser than 300-micron IS Sieve for fine aggregate and coarser than 4.75-mm

IS Sieve for coarse aggregate).

Reporting

of results:-

The percentage of light-weight pieces (coal and

lignite) in the aggregate shall be reported to the nearest 0.1 %.

Safety and Precautions While Testing:-

- Clean the apparatus thoroughly before testing and after testing.

- The test should be performed away from vibrations and other disturbances.

- Harmless organic materials may cause colouration and certain naturally occurring organic compounds do not cause coloration.

- Recovery of the bromoform in the bromoform-benzene mixture can be affected by running and stream of water through the mixture until all benzene has been dissolved and removed.

- Caution: The

chemicals listed above are highly toxic, both by absorption through the skin

and by inhalation. They shall be used only in a hood, and care shall be taken

to avoid contact with the skin or inhalation of the fumes.

- For determining coal and lignite, the heavy liquid used shall have a specific gravity 2.00±0.01.

|

Thanks for reading this article.

Please, don’t forget to share it. |