What is Vee Bee Consistometer Test?

Vee bee consistometer test is named after the Sweden

developer V Bahrmer and it is covered by IS: 1199–1959. It is used to determine

workability of concrete using consistometer. It is usually performed on dry and

fresh concrete and it is not suitable for very wet concrete.

Vee bee consistometer test carries out the relative effort

measurement to change the mass of the concrete mix from one definite shape to

another definite shape (from the slump conical shape to the cylindrical shape)

by conducting vibration process. This effort is known as remoulding effort and

the measurement of the effort is done by time measurement in seconds. It is

called as Vee Bee Seconds.

When the concrete mix having slump value more

than 50 mm remoulds quicker where measuring the time is not possible, the time

* Vee-bee

consistometer test is specially used for determining very low

workability of concrete mix.

Vee Bee Test of Concrete Procedure, Vee Bee Consistometer Test as per IS Code 1199:1959

Hi

friends, you are welcomed in the world of Civil Allied Gyan. "Read here

definition, apparatus, IS code, test procedure, formula, result and lab report about vee-bee

consistometer test of concrete for workability."

By

the help of this you can easily determine

the workability of dry and fresh concrete by vee-bee consistometer test.

Apparatus Required for Vee Bee Consistometer Test:-

- Vee-Bee consistometer test apparatus

- Sheet metal slump cone

- Stopwatch

- Standard iron graduated rod

- Weighing balance

- Tamper (16 mm in diameter and 600 mm length)

- Trowels

- Glass disc

- Cylindrical containers

Vee Bee Test Machine

(Apparatus)

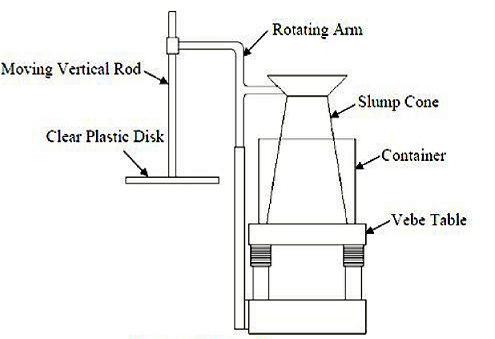

Vee bee test machine (apparatus) consists

of a vibrating table which is mounted on an elastic support. The vibrator is

operated electrically. The length and width of a vibrating table are respectively

380 mm and 260 mm.

On the surface of the vibrating table, a cylindrical

container is attached using wing nuts. Slump cone and a cylindrical jar are

placed as shown in the figure. The sheet metal cylindrical container is screwed

to the vibrating table through wingnuts.

The slump cone, of height 300 mm which is

open on both sides and has a diameter of 200 mm at the bottom and 100 mm at the

top, is inserted into the cylindrical container to perform the test.

The graduated rod which has a scale is

used for measuring the workability of the sample.

As shown as in the figure, the whole

arrangement is mounted on a sturdy base. The base consist of a swivel arm

holder. There is another swivel arm that consist of a funnel and a guide sleeve

is fixed into it.

A standard iron graduated rod is fixed to the

swivel arm through the guide sleeve. It has the provision for screwing the

transparent disc.

The bottom base consists of a swivel arm holder where the

swivel arm is fixed to the funnel and guide sleeve as shown in the figure.

IS Code for Vee Bee Consistometer Test of Fresh Concrete

- IS: 1199-1959, Methods of sampling and analysis of concrete mix

- IS: 456-2000, Code for practice of reinforced and plain concrete

- IS: 10510:1983, Specifications for vee-bee consistometer

Procedure for Vee Bee Consistometer Test of Concrete:-

- The sheet metal slump cone is filled with four layers of concrete. Each layer of concrete is one fourth the height of the cone.

- The sheet metal slump cone is placed inside the sheet metal cylindrical container that is placed in the consistometer.

- The as described earlier is performed to find the slump value (in mm).

- The glass disc attached to the swivel arm is turned and placed on the top of the concrete in the slump cone placed inside the cylindrical container.

- Then the electrical vibrator is switched on and at the same time a stop watch is started. The concrete is allowed to spread out in the sheet metal cylindrical container.

- Until the slump conical shape of the concrete disappears and the concrete assumes a cylindrical shape, the vibration is continued. This can be decided by observing the glass disc from the top for disappearance of transparency.

- When the concrete fully changed to a cylindrical shape, immediately the stopwatch is switched off.

- The time required for the shape of concrete to change from slump cone shape to cylindrical shape in seconds is recorded. This time is expressed as Vee Bee Degree or Vee Bee Seconds. It gives us the measure of workability of the fresh concrete.

*This method is very suitable for very dry and fresh concrete

whose slump value cannot be measured by Slump

Test,

but the vibration is too vigorous for concrete with a slump value more than

about 50 mm.

Observations:-

- Type of cement=……………….

- Brand of cement=……………….

Table 1:

Table 2: Consistency

Measurement for Different Workability Mix in Slump Test, Compaction Factor Test

and Vee-Bee Test

Workability Description

|

Workability Measurement

|

||

Slump (in mm)

|

Compaction Factor

|

Vee-bee degree (in second)

|

|

Extremely Dry

|

-

|

-

|

32-18

|

Very Stiff

|

-

|

0.70

|

18-10

|

Stiff

|

0-25

|

0.75

|

10-5

|

Stiff Plastic

|

25-50

|

0.85

|

5-3

|

Plastic

|

75-100

|

0.90

|

3-0

|

Flowing

|

150-175

|

0.95

|

-

|

Results:-

The Vee-Bee

degree (or Vee-Bee seconds) = ……… seconds.

Report:-

The

result of Vee-Bee consistometer test is a time period. This time is expressed

as vee bee degree or vee bee seconds.

|

Thanks for reading this article. Please, don’t

forget to share it. |

Informative

ReplyDelete