What is Compaction Factor Test of Concrete Mix?

What is Compaction Factor?

|

Compaction Factor Test of Concrete: Procedure Lab Report pdf as per IS Code: 1199-1959

Hi

friends, you are welcomed in the world of Civil Allied Gyan. "Read here

definition, apparatus, IS code, test procedure, formula, result and lab report

for compaction factor test of concrete to find workability."

By

the help of this you can easily find the consistency or workability of concrete

by compaction factor test.

Apparatus Required for Compaction Factor Test of Concrete:-

- Compaction factor apparatus

- Weighing balance

- Tamping rod

- Trowel

- Scoop about 150 mm long

- Tamper (16 mm in diameter and 600 mm length)

- Ruler

- Containers and tools for mixing or concrete mixer etc.

|

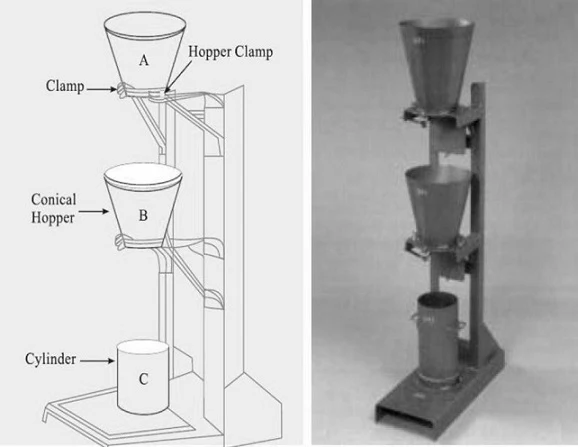

What is Compaction Factor Apparatus?

1. Upper Hopper

|

Dimensions in cm.

|

Top internal

dia.

|

25.4

|

Bottom

|

12.7

|

Internal height

|

27.9

|

2. Lower Hopper

|

Dimensions in cm.

|

Top internal

dia.

|

22.9

|

Bottom

|

12.7

|

Internal height

|

22.9

|

3. Cylinder

|

Dimension in cm.

|

Internal

Diameter

|

15.2

|

Internal Height

|

30.5

|

IS Code of Compaction Factor Test for Concrete Mix:-

- IS: 1199-1959, Methods for sampling and analysis of concrete mix

- IS: 5515-1983, Specification for compressive factor apparatus

Procedure for Compaction Factor Test of Concrete:-

- Preparation of Specimens:-

Prepare four mixes with W/C ratios 0.4, 0.5, 0.55, 0.6 and 0.65. For each mix

take 5 kg of fine aggregate, 10 kg of coarse aggregate and 2.5 kg of cement.

- Grease the inner surface of the hoppers and the cylinder and fasten the hopper doors.

- Weigh the empty cylinder accurately (W₁ Kg) and fix the cylinder on

the base with nuts and bolts.

- Mix coarse and fine aggregates and cement dry until the mixture gets uniform in colour and then add water mix until concrete appears to be homogeneous.

- Fill the sample of concrete to be tested in upper hopper gently with trowel without compacting. The hopper is filled level with its brim.

- Now open the trap door of the upper hopper and allow the concrete mixes to fall into the lower hopper bringing the concrete into standard compaction.

- If concrete has a tendency to stick to the sides of the hopper, the concrete should be slowly pushed down by inserting the tamping rod into the concrete mix.

- Immediately after the concrete comes to door of the lower hopper, open the trap door of the lower hopper and allow the concrete mixes to fall into the cylinder, bringing the concrete into standard compaction.

- Cut off the excess of concrete

above the top of the cylinder and make level with trowels. Wipe the outside of

cylinder cleanly.

- Find

the weight of cylinder i.e. cylinder filled with partially compacted concrete (W₂ Kg).

- Refill the cylinder with the same sample of concrete mixes in approx. 4 layers, tamping each layer with tamping rod for 25 times in order to obtain full compaction of concrete mix.

- The top of fully compacted concrete mix should be carefully struck off level with top cylinder. The outside of the cylinder is wiped a clean.

- Weigh

the cylinder filled with fully compacted concrete (W₃ Kg).

- Repeat the procedure different-different for different a trowel.

Observations and Calculations:-

Weight

of cylinder = W₁ (in

kg)

Weight

of cylinder + partially compacted concrete = W₂

Weight

of Partially compacted concrete = W₂‒W₁

Weight

of cylinder + fully compacted concrete = W₃

Weight

of fully compacted concrete = W₃‒W₁

Results:-

Compaction factor is = ……………. or

Maximum

workability of concrete is occurring at a water/cement (W/C) ratio of ………….

Report:-

The

compaction

factor of concrete is reported as the ratio of the weight of partially

compacted concrete to the weight of fully compacted concrete. The value of compaction

factor shall normally be stated to the nearest second decimal place.

Degree of Workability

|

Compacting Factor

|

Very Low

|

0.75 to 0.8

|

Low

|

0.8 to 0.85

|

Medium

|

0.85 to 0.92

|

High

|

0.92 & above

|

Workability

|

Compaction Factor

|

Slump (mm)

|

Very Low

|

0.78

|

0 - 25

|

Low

|

0.85

|

25

- 50

|

Medium

|

0.92

|

50 - 100

|

High

|

0.95

|

100

- 175

|

Thanks for reading this

article. Please, don’t forget to share it.