What is this blog post about?

Dear readers, in this blog post we have covered the Atterberg Limits Test (Liquid, Plastic and Shrinkage Limits) with knowledgeable discussion of definitions, apparatus list, test procedure, calculation & lab report. The Atterberg limits of soil comprise liquid limit, plastic limit and shrinkage limit and are also called the consistency limits of soil.

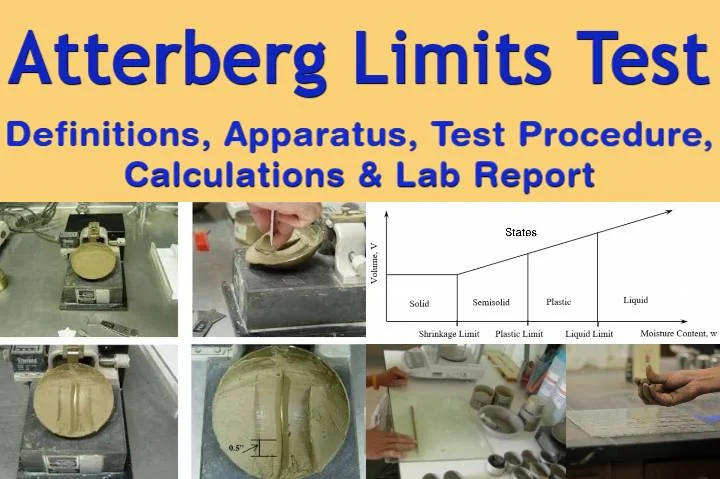

In soil mechanics, the presence of moisture content has always been considered an important and reliable indication of the behavior of cohesive soil. The presence of clay minerals in a fine-grained cohesive soil allows it to re-mold in the presence of some moisture without crumbling. If a clay slurry is dried, the moisture content gradually decreases and it passes from liquid state to plastic state. On further drying it changes into semisolid state and finally to a solid state (as shown in Figure). Thus a fine-grained soil may be in any of the four states depending on the water content in the soil system.

The four states can defined as follows:A. Liquid State:

The state at which a fine-grained soil will flow on its own weight called the liquid state.

B. Plastic State

The state at which the soil can be re-molded to any shape without any development of cracks called the plastic state.

C. Semi Solid State

Semi-solid is the state of soil at which it can be re-molded but only with the development of cracks.

D. Solid State

Solid state is the state of soil at which the soil cannot be re-molded at all and if done the soil specimen would get broken.

Atterberg Limits Test - Definition, Apparatus, Test Procedure, Calculation & Lab Report | Atterberg Limits of Soil

In 1911, Albert Mauritz Atterberg, a Swedish soil scientist and chemist, identified that a gradual decrease in water content of a clay slurry causes it to passes through different states. He developed a method for describing the limit consistency of fine-grained cohesive soils on the basis of moisture content. These limits are liquid limit (LL), plastic limit (PL) and shrinkage limit (SL).

What are Atterberg Limits

In 1911, A. M. Atterberg, a Swedish soil scientist, identified the three limiting water contents, in between the soil states, that are commonly known as Atterberg limits. These limits are liquid limit (LL), plastic limit (PL) and shrinkage limit (SL) which are described below.

A. Liquid Limit (LL)

The liquid limit is the water content at which the soils passes from liquid state to plastic state and certainly gains a small shearing strength. It is the minimum water content at which the soil exists in the liquid state and the maximum water content at which the soil exists in a plastic state. In short, Liquid Limit is the water content at which the fine-grained soil tends to flow like a liquid.

B. Plastic Limit (PL)

The Plastic Limit is the water content at which the soil changes from a plastic state to a semisolid state and whereby gains a small shearing strength. It is the water content at which soil begins to behave as a plastic material and below which it stop to behave like a plastic material. It starts to crumble when rolled in threads of 3 mm diameter. In short, Plastic Limit is the water content at which a fine-grained soil cannot be remolded without cracking.

C. Shrinkage Limit (SL)

The shrinkage limit is the water content (or moisture content) of the soil at which the water is just sufficient to fill all the pores of the soil and the soil is just saturated. This is the water content at which further reduction in water content does not cause any significant decrease in the volume of the soil.

What is Atterberg Limits Test

The Atterberg Limits Test are a group of standardized tests that are performed on the fraction of fine-grained soils, such as silts and clays, that will pass through a No. 40 or 425µm standard sieve to determine their properties under different moisture contents. There are three Atterberg Limits Tests that are commonly performed: liquid limit test, plastic limit test and shrinkage limit test.

A. Liquid Limit Test

The Liquid Limit Test determines the required water content in soil at which the soil changes from the liquid state to the plastic state. The test involves repeatedly dropping a standard device onto a soil sample from a specific height and determining the number of drops required to close a groove of standard dimensions.

B. Plastic Limit Test

The Plastic Limit Test determines the required water content at which a soil changes from a plastic state to a semisolid state. The test involves rolling a soil sample into a thread of standard dimensions until it crumbles, and measuring the water content at which the thread can no longer be rolled without breaking.

C. Shrinkage Limit Test

The Shrinkage Limit Test determines the required water content at which a soil no longer shrinks when further dried. The test involves shaping a soil sample into a cylinder and allowing it to dry in an oven. The sample is then re-weighed and the moisture content is calculated.

Atterberg Limit Test ASTM Code

“ASTM D4318” is the standard test methods for Atterberg Limit Tests (Liquid Limit, Plastic Limit, and Plasticity Index of Soils).

Atterberg Limits Test IS Code

“IS 2720 Part-5” is the IS code for both Liquid Limit and Plastic Limit test that are collectively known as Atterberg Limits Test.

Atterberg Limit Test Apparatus

The apparatus list for sample preparation and determination of Liquid Limit, Plastic Limit, and Shrinkage Limit of soil consists of:

| Apparatus | Discription |

|---|---|

| Evaporating dishes | To mix specimen to desired moisture content. |

| Spatula | To mix, form and smooth the soil specimen. |

| Aluminum containers | For soil moisture samples. |

| Mortar and pestle | To reduce particle size. |

| Digital scale | With 0.01g readability. |

| Drying oven | For moisture content test. |

| Liquid limit test apparatus including liquid limit machine and Casagrande grooving tool. | |

| Plastic limit test apparatus including plastic limit roller and glass plate. | |

| Shrinkage limit test apparatus including shrinkage dish, microcrystalline wax, petroleum jelly, fine thread, glass plate, and wax melting pot. | |

Atterberg Limit Test Procedure

For each test the soil samples shall be consist of the fraction of soil that is able to pass through a No. 40 or 425µm sieve and shall be prepared using standard methods. Moisture will be adjusted by adding water and thoroughly mixing it. After preparation of soil sample as per standard method the test procedure will be conducted as below.

Liquid Limit Test Procedure

- Weigh each of the three moisture cans (W₁).

- Calibrate the drop of the cup, using the end of the grooving tool not meant for cutting, so that there is consistency in the height of the drop.

- Put about 250g of air-dried soil sample through a 425µm sieve into an evaporating dish and mix thoroughly adding enough distilled water to form a uniform paste.

- Adjust its water content until the constancy requires about 25 to 35 blows of the Casagrande's liquid limit device to close the groove.

- Place a portion of the soil paste in the Casagrande’s cup and spread it smoothly using a spatula so that the maximum depth is about 10mm.

- Take care to eliminate air bubbles from the soil pat, but form the pat with as few strokes as possible.

- Keep the unused soil in the mixing/storage dish.

- Cover the evaporating dish with a wet towel (or use other means) to retain the moisture in the soil.

- Cut a 2mm groove at the center line of the soil cup using the grooving tool.

- Verify that no crumbs of soil are present on the base or the underside of the cup.

- Lift and drop the cup by turning the crank at a rate of 2 drops per second until the two halves of the soil pat come in contact at the bottom of the groove along a distance of 1/2 inch or 13 mm.

- Count the number of drops (N) required to close the groove.

- Verify that an air bubble has not caused premature closing of the groove by observing that both sides of the groove have flowed together with approximately the same shape.

- If an air bubble has caused premature closing of the groove, reform the soil in the cup, adding a small amount of soil to make up for that lost in the grooving operation and repeat the above procedure.

- If the soil slides on the surface of the cup, repeat the above procedure at a higher water content.

- If, after several trials at successively higher water contents, the soil pat continues to slide in the cup or if the number of blows required to close the groove is always less than 25, record that the liquid limit could not be determined, and report the soil as non-plastic without performing the plastic limit test.

- If N = 15 to 35, collect the soil sample from the closed part of the cup using a spatula and place in a container.

- Determine the water content weighing the can + moist soil (W₂).

- Transfer the remaining soil in the cup to evaporating dish. Then clean and dry the cup and grooving tool.

- Increase the water content of the soil adding distilled water and decrease the number of blows required to close the groove.

- Repeat the process for at least two additional trials producing successively lower numbers of blows to close the groove. One of the trials shall be for a closure requiring 25 to 35 blows, one for closure between 20 and 30 blows, and one trial for a closure requiring 15 to 25 blows.

- Determine the corresponding water content of the soil specimen from each trial.

- Plot the relationship between the water content (w%) and the corresponding number of drops (N) of the cup on a semilogarithmic graph with the water content (w%) as ordinates and the number of drops (N) as abscissas on a logarithmic scale.

- Draw the best straight line through the three or more plotted points.

- Determine the corresponding water content at 25 no. of blows which is the liquid limit of the sample.

Plastic Limit Test Procedure

- Select approximately 20g of soil from the material prepared for liquid limit test or prepare the soil paste as mentioned in liquid limit test.

- Reduce the moisture content of the soil paste to a consistency at which it can be rolled without sticking to the hands by spreading or mixing continuously on the glass plate.

- Determine the weight of the empty moisture can (W₁).

- Select a 1.5g to 2.0g portion of the soil and form the selected portion into an ellipsoidal-shaped mass rolling the soil between the fingers and the glass plate with just sufficient pressure to roll the mass into a thread of uniform diameter throughout its length.

- Prepare several ellipsoidal-shaped mass and place them in the plastic limit device.

- Place two fresh sheets of filter paper on either face of the plates.

- Roll the upper half of the device which has a calibrated opening of 3.2 mm with the lower half plate.

- If the soil crumbles forming a thread approximately the size of the opening between the plates (3.2 mm diameter), collect the crumbled sample and determine the weight of can + moist soil (W₂).

- Repeat the test procedure with the same soil, but dry it by rolling it between your palms until the thread crumbles under the pressure required for rolling and the soil can no longer be rolled into a 3.2 mm diameter thread.

- Determine the weight of the dry soil + moisture can (W₃).

- Determine the weight of water (W₂ – W₃) and dry soil (W₃ – W₁).

- Determine the water content by the formula: (weight of water)/(weight of dry soil)×100%.

- The water content obtained is the plastic limit of the soil.

Plasticity Index

Calculate the plasticity index as follows:

PI = LL – PL

where:

LL = liquid limit, and

PL = plastic limit.

Note: Both LL and PL should be whole numbers.

Shrinkage Limit Test Procedure

The Shrinkage Limit test is performed by molding a soil pat of moist test sample into a special shrinkage dish. The shrinkage dish and soil are oven-dried and weighed. Then the volume of the specimen is determined by water displacement. The test method is described in ASTM D4943 and IS 2720 Part-6. Visit here to read all about shrinkage limit test.

Atterberg Limit Test Discussion (Observation & Calculation)

Observation of Liquid Limit Test

| Trial No. | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| Number of blows, N | |||||

| Wt. of container (in g) | |||||

| Wt. of container + moist soil in g | |||||

| Wt. of container + dry soil in g | |||||

| Wt. of water, Ww (in g) | |||||

| Wt. of dry soil, Ws (in g) | |||||

| Water content, w (in %) |

Calculation of Liquid Limit Test

(A Sample Calculation)

For Trial No. 01,

Number of blow, N= 15 (recorded during test)

Wt. of container = 7.7 g

Wt. of container + moist soil = 27.6 g

Wt. of container + dry soil = 19.2 g

Wt. of water, Ww = 27.6 – 19.2 = 8.4 g

Wt. of dry soil, Ws = 19.2 – 7.7 = 11.5 g

Water content, w = 73.0 %

The flow curve, as shown in the Figure below the liquid limit test procedure, can be obtained by plotting the water content with the corresponding number of blows on semi-log graph paper. The liquid limit of the soil sample can be obtained which will be the corresponding water content at 25 no. of blows.

Observation of Plastic Limit Test

| Trial No. | 1 | 2 | 3 |

|---|---|---|---|

| Wt. of container (in g) | |||

| Wt. of container + moist soil in g | |||

| Wt. of container + dry soil in g | |||

| Wt. of water, Ww (in g) | |||

| Wt. of dry soil, Ws (in g) | |||

| Water content, w (in %) |

Calculation of Plastic Limit Test

(A Sample Calculation)

For Trial No. 01,

Wt. of container = 7.7 gm

Wt. of container + wet soil = 23.2 gm

Wt. of container + dry soil = 20.9 gm

Wt. of water, Ww = 23.2 – 20.9 = 2.3 gm

Wt. of dry soil, Ws = 20.9 – 7.7 = 13.2 gm

Water content, w = 17.42 %

Note: Plastic Limit of soil is determined as the average of water content of all the three trials.

Calculation of Plasticity Index (PI)

Formula:

Plasticity Index (PI) = Liquid Limit (LL) – Plastic Limit (PL)

Calculation of Liquidity Index (LI)

Formula:

LI = (PL − Natural Water Content) ÷ PI

Calculation of Consistency Index (CI)

Formula:

CI = (LL − Natural Moisture Content) ÷ PI

Atterberg Limit Test Lab Report

The Atterberg Limit Test report should include the following:

- Objective of the test

- Applications of the test

- Apparatus used in the test

- Test method (optional)

- Analysis of test results – Complete the table provided and show one sample calculation (mentioned in observation & calculation).

- The value for liquid limit, flow index, plastic limit, plasticity index and shrinkage limit nearest to the whole number.

- Summary and conclusions – Comment on the Atterberg limit values of the given soil sample.

- Report the soils as highly plastic or moderately plastic or non- plastic as per calculation and result.

- If either the liquid limit or plastic limit could not be determined, or if the plastic limit is equal to or greater than the liquid limit, the soil will be reported as non-plastic, NP.

Conclusion

The Atterberg Limits tests are important in geotechnical engineering as they provide useful information for soil engineering and construction applications. These limits are used globally for soil identification, classification, and strength correlations. For example, these limits are used to indicate the plasticity of fine-grained cohesive soil by differentiating them between highly plastic, moderately plastic and non- plastic soils. These limits can help to determine the suitability of a soil for a specific construction project, as well as its behavior under different loads and conditions.

FAQs

What are Atterberg limits?

The water content at which the fine-grained cohesive soils transition between one state to the other is known as consistency limits or Atterberg limits. The Atterberg limits comprise the liquid limit, plastic limit and shrinkage limit.

What is Atterberg limit test?

The Atterberg limits test comprise of the liquid limit test, plastic limit test and shrinkage limit test of soil. These tests are performed on fine-grained cohesive soils for their identification, classification, and strength correlations.

Why do we use Atterberg limit test?

The Atterberg limits test are used internationally because they help in soil identification, classification, and strength correlations. For example, the Atterberg limits distinguish between silt and clay and also distinguish between different types of silts and clays.

What are the three Atterberg limits?

The liquid limit, plastic limit, and shrinkage limit are the three Atterberg limits.

What is Atterberg liquid limit?

The Atterberg liquid limit is the moisture content at which the fine-grained soils transition between liquid state and plastic state. At minimum limit the soil tends to flow like a liquid and at maximum limit the soil no longer flows like a liquid.

What is Atterberg plastic limit?

The Atterberg plastic limit is the moisture content at which the fine-grained soils transition between plastic state and semi-solid state. At plastic limit a fine-grained soil can no longer be re-molded without cracking.

You May Like to Read

Importance of Atterberg Limits