What are in this post?

This blog post covers definition, apparatus list, IS code, test procedure, calculation and lab report of direct shear test of soil which is a method to determine shear strength test of soil as per IS 2720 (Part-13) 1986.

What is Direct Shear Test of Soil?

Direct Shear Test of Soil is a laboratory or field test that is performed to determine the shearing strength of soil with a maximum particle size of 4.75 mm in undrained, consolidated undrained and consolidated drained conditions. It is also called Box Shear Test. This test is more suitable for cohesionless soil. It is also used to find out discontinuities in soil or rock masses.

Note:- The undrained test can be performed only for highly impermeable clays. When silty clays and silts are involved, partial drainage is inevitable. This fact should be recognised while interpreting the results.

Importance and Uses of Direct Shear Test of Soil

In many engineering problems such as design of foundation, retaining walls, slab, bridges, pipes, sheet piling, the value of the angle of internal friction and cohesion of the soil involved are required for the design. Direct shear test of soil is used to predict these parameters quickly. The test procedures for determining these values for cohesionless soils are covered here.

Shear Strength of Soil by Direct Shear Test of Soil as per IS 2720 Part 13 1986

Read here the test procedure of direct shear test of soil and apparatus list as per IS 2720 Part-13 1986. The data calculation sheet for direct shear test is also provided here.

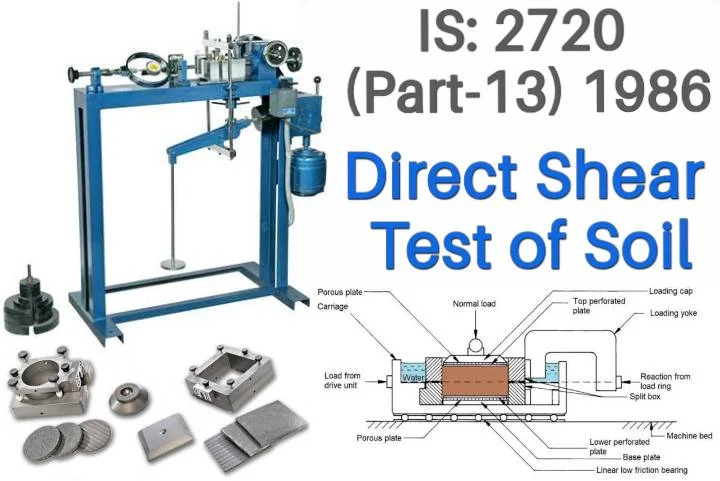

Apparatus List for Direct Shear Test of Soil

The apparatus used in shear strength test of soil by direct shear test are

- Direct Shear Box (including shear box grid plates, porous stones, base plates, loading pad and water jacket that conform to IS : 11229-1985)

- Loading Frame (motor attached)

- Proving-Ring (fitted with a dial-gauge accurate to 0.002 mm to measure the shear force taken by the soil initiated in the shearing plane)

- Micrometer Dial Gauges (accurate to 0.01 mm; one suitably mounted to measure horizontal movement and the other suitably mounted to measure the vertical compression of the specimen)

- Weighing Balance (of 1 kg capacity and sensitive to 0.1 g)

- Sieve (4.75 mm)

- Spatula

- Straight Edge

- Sample Trimmer or Core Cutter

- Box Container

The Loading Frame must satisfy the following requirements:

- The vertical stress on the sample shall remain vertical and constant during the test and there shall be arrangement to measure compression.

- The shear stress or strain can be applied in the dividing plane of the two parts of the shear box.

- It shall be possible to maintain a constant rate of increase in stress during the test (irrespective of the strain rate) with arrangement to get different rates of stress increase.

- In case of a strain-controlled apparatus, the strain rate should remain constant irrespective of the stress. Suitable arrangement shall be provided to obtain different strain rates.

- No vibrations should be transmitted to the sample during the test and there should not be any loss of shear force due to friction between the loading frame and the shear box-container assembly.

IS Code for Direct Shear Test of Soil

The Indian Standards code i.e. IS Code for direct shear test of soil is IS: 2720 (Part 13) 1986. It is reaffirmed in 2016.

Preparation Of Specimen for Direct Shear Test of Soil

One kg of air dry sample of soil passing through 4.75mm IS sieve is required for this test.

1. Undisturbed Specimen

Specimens of required size shall be prepared from the undisturbed specimen collected from field in accordance with IS : 2720 (Part 1)-1983.

2. Remoulded Specimens

a. Cohesive soils may be compacted to the required density and moisture content, the sample extracted and then trimmed to the required size. Alternatively, the soil may be compacted to the required density and moisture content directly into the shear box after fixing the two-halves of the shear box together by means of the fixing screws.

b. Cohesionless soils may be tamped in the shear box itself with the base plate and grid plate or porous stone as required in place at the bottom of the box.

c. The cut specimen shall be weighed and trimmings obtained during cutting shall be used to obtain the moisture content. Using this information, the bulk dry density of the specimen in the shear box shall be determined.

Test Procedure for Direct Shear Test of Soil

Part-1: Undrained Test

- Measure the dimensions of shear box. This helps in finding volume of specimen.

- Set up the shear box by fixing its upper part to the lower part with clamping screws.

- Weigh an initial amount of soil specimen in a pan.

- Place the soil specimen into the shear box in three layers. Each layer should be compacted with a tamper.

- Weigh the empty pan and calculate the mass of soil thus used.

- Now, calculate the density of soil by dividing mass of used soil by volume of shear box.

- Make the surface of the soil plane.

- Place plain grid plate on the base plate at the bottom of the specimen, and the plain grid plate on top of the specimen into the loading frame. The serrations of the grid plates should be at right angles to the direction of shear (see note*).

- Place the loading pad on the top grid plate. The water jacket should be provided so that the sample does not get dried during the test.

- Apply the required normal stress and adjust the rate of longitudinal displacement/shear stress application so that no drainage occurs in the specimen during the test.

- Raise the upper part of the shear box such that a gap of about 1 mm be left between the two parts of the box.

- Start the motor with a selected speed.

- Set the dial gauges zero, before starting the experiment. All the readings should be recorded carefully.

- Now, conduct the test by applying a horizontal shear load until the the shear load peaks and then falls or longitudinal displacement reaches 20% of the specimen length, whichever occurs first.

- Record the shear load reading indicated by the proving ring assembly and note the corresponding longitudinal displacement at regular intervals.

- If necessary, the vertical compression, if any, of the soil specimen may be measured to serve as a check to ensure that drainage has not taken place from the soil specimen.

- At the end of the test, remove the specimen from the shear box and then determine the final moisture content.

- Repeat the test on seperate specimens of same density under different normal stress values. A minimum of three (preferably four) tests should be conducted.

Note*: As porous stones are not used for the undrained tests, plain plates of equal thickness should be substituted in their place so as to maintain the shear plane in the sample in the middle of its thickness.

Part-2 Consolidated Undrained Test

- Assemble the direct shear apparatus according to Part-1: Undrained Test (paragraph 1 to 7).

- Place perforated grid plates and saturated porous stones at the top and bottom of the specimen into the loading frame.

- Place the loading pad on the top grid plate. The water jacket should be provided so that the sample does not get dried during the test.

- Apply the required normal stress and adjust the shear rate such that water does not drain from the specimen at the time of application of the shear load.

- The shear test should be conducted only after complete consolidation has occurred under the particular normal stress.

- Now proceed as Part-1 (paragraph 11 and onwards) and record the vertical compression of the soil with time [IS: 2720 (Part 15)-1986].

Part-3 Consolidated Drained Test

- Assemble the direct shear apparatus according to Part-1: Undrained Test (paragraph 1 to 7).

- Place perforated grid plates and saturated porous stones at the top and bottom of the sample into the loading frame.

- Place the loading pad on the top grid plate. The water jacket should be provided so that the sample does not get dried during the test.

- Apply the required normal stress which is done in increments (see IS: 2720 Part-15 1986), the sample should be allowed to consolidate.

- When the consolidation has completely occurred, the shear test should be done at such a slow rate that at least 95 percent pore pressure dissipation occurs during the test in this calculated time factor.

- Now proceed as Part-1 (paragraph 11 and onwards) and record the vertical compression of the soil with time.

Calculations and Report

1. From the calibration chart of the proving-ring, the loads corresponding to the load dial readings obtained during the test should be calculated. The loads so obtained divided by the corrected cross-sectional area of the specimen gives the shear stress in the sample. The corrected cross-sectional area shall be calculated from the following equation:

Corrected Area = A៰(1 - δ/3)

Where,

A៰ = initial area of the specimen in cm² and

Location of samples : ...............

Rate of Strain : ..............

Bore hole No. : ..............

Sample No. : ............

Proving-ring/load cell No. : ............

Calibration curve : ............

Load-hanger lever ratio : ............

Soil Specimen Measurements

Dimensions : ...................

Area of specimen : .................

Thickness : ...................

Volume of specimen : ................

lnitial wet weight of specimen : .................

Moisture content : .............. (Average of .......... tests)

Bulk density : ................

Final wet weight of the specimen : ................

Moisture content at shear zone : ..................

Consolidation

Hanger load : .............

Applied load : .............

Normal stress : ............

δ = displacement in cm.

2. The longitudinal displacement at a particular load may be either noted directly from the strain dial readings or calculated as the product of the corresponding time reading and the strain rate, allowing for the compression of the proving-ring, where applicable. The stress longitudinal displacement readings should be plotted and the maximum stress and corresponding longitudinal displacement together with the normal load applied during the test recorded.

Note: In general, failure in direct shear may be considered to take place either at maximum shear or at the maximum obliquity of the Mohr failure envelope. If the failure is assumed to take place at maximum shear and not at maximum obliquity, the angle of shearing resistance thus obtained will be smaller, giving an error, if any, on the safe side. It should, however, be noted that differences in the values of the angle of shearing resistance obtained by using the two criteria mentioned above are more important for sands than for clays.

3. The maximum shear stress and the corresponding longitudinal displacement and applied normal stress should be recorded for each test and the results should be presented in the form of a graph in which the applied normal stress is plotted as abscissa and the maximum shearing stress is plotted as ordinate to the same scale. The angle which the resulting straight line makes with the horizontal axis and the intercept which the straight line makes with the vertical axis shall be reported as the angle of shearing resistance and cohesion intercept respectively.

Note: The normal stress-maximum shear stress relationship may not be a straight line in all cases. In such cases, the shear parameters may be obtained by drawing a tangent to the normal stress expected in the field.

4. In the case of the consolidated undrained and consolidated drained tests, the load at which the specimen is consolidated and the consolidation characteristics as determined during the consolidation part of the test should also be reported.

Observations and Recordings

Proforma for Recording Test Results

Project Name : ................Location of samples : ...............

Rate of Strain : ..............

Bore hole No. : ..............

Sample No. : ............

Proving-ring/load cell No. : ............

Calibration curve : ............

Load-hanger lever ratio : ............

Soil Specimen Measurements

Dimensions : ...................

Area of specimen : .................

Thickness : ...................

Volume of specimen : ................

lnitial wet weight of specimen : .................

Moisture content : .............. (Average of .......... tests)

Bulk density : ................

Final wet weight of the specimen : ................

Moisture content at shear zone : ..................

Consolidation

Hanger load : .............

Applied load : .............

Normal stress : ............

| Date and Timing | Vertical Dial Reading | Vertical Dial Difference | Thickness of Specimen |

|---|---|---|---|

| 1 | |||

| 2 | |||

| 3 | |||

| 4 |

Shearing Stage

Rate of Shearing .............. mm/min

*Scroll table horizontally for full view.

| Date and Time | Displacement Dial Reading | Displacement, δ | Area Correction | Corrected Area | Stress Dial Reading | Shear Force | Shear Stress | Vertical Dial Reading | Vertical Dial Diffrence | Thickness of Specimen |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | ||||||||||

| 2 | ||||||||||

| 3 | ||||||||||

| 4 |

Plot Shear normal stress displacement curve and find :

(a) Maximum shear stress and

(b) Corresponding shear displacement

Summary of Results

| Test No. | Normal Stress | Shear Strees at Failure | Shear Displacement at Failure | Initial Water Content | Final Water Content | Remarks |

|---|---|---|---|---|---|---|

| 1 | ||||||

| 2 | ||||||

| 3 | ||||||

| 4 |

*Scroll table horizontally for full view.

Plot Shear normal stress displacement curve and find :

(a) Cohesion intercept and

(b) Angle of Shearing resistance

General Remarks on Shear Strength Test of Soil

- In the shear box test, the specimen is not failing along its weakest plane but along a predetermined or induced failure plane i.e. horizontal plane separating the two halves of the shear box. This is the main draw back of this test. Moreover, during loading, the state of stress cannot be evaluated. It can be evaluated only at failure condition i.e Mohr’s circle can be drawn at the failure condition only. Also failure is progressive.

- Direct shear test of soil is simple and faster to operate. As thinner specimens are used in shear box, they facilitate drainage of pore water from a saturated sample in less time. This test is also useful to study friction between two materials, one material in lower half of box and another material in the upper half of box.

- The angle of shearing resistance of sands depends on state of compaction, coarseness of grains, particle shape and roughness of grain surface and grading. It varies between 28°(uniformly graded sands with round grains in very loose state) to 46°(well graded sand with angular grains in dense state).

- The volume change in sandy soil is a complex phenomenon depending on gradation, particle shape, state and type of packing, orientation of principal planes, principal stress ratio, stress history, magnitude of minor principal stress, type of apparatus, test procedure, method of preparing specimen etc. In general loose sands expand and dense sands contract in volume on shearing. There is a void ratio at which either expansion contraction in volume takes place. This void ratio is called critical void ratio. Expansion or contraction can be inferred from the movement of vertical dial gauge during shearing.

- The friction between sand particle is due to sliding and rolling friction and interlocking action. The ultimate values of shear parameter for both loose sand and dense sand approximately attain the same value so, if angle of friction value is calculated at ultimate stage, slight disturbance in density during sampling and preparation of test specimens will not have much effect.

- Rate of strain and rate of shearing should be decided after analyzing consolidation-time data in the case of drained tests.

- IS:2720 (Part-13) covers the methods for determination of shear strength of soil with a maximum particle size of 4.75mm in undrained, consolidated undrained and consolidated drained conditions.

Rate of Shear for Consolidated Drained Test

Calculation of Rate of Strain

For sandy soils, a rate of strain of 0.2 mm/min may be suitable. For clayey soils, a rate of strain of 0.01 mm/min or slower may be used but actual rate of strain suitable for the soil under test may be ascertained as given below.

From the consolidation data collected, the compression dial readings should be plotted against the logarithm of time and from this curve, the value of coefficient of consolidation, C៴, should be computed from the formula:

C៴ = 0.197(h²/t₅₀)

where,

C៴ = coefficient of consolidation,

2h = initial thickness of the specimen, and

t₅₀ = time corresponding to 50 percent consolidation.

The requisite time to failure when theoretically 95 percent dissipation is ensured, may be obtained from the following equation:

t₁ = h²/[nC៴(1–Uс)] = 20h²/3C៴

where,

t₁ = time to failure,

2h = initial thickness of the specimen,

n = a constant for drainage from both ends = 3, and

Uc = degree of pore pressure dissipation.

From a knowledge of approximate strain expected at failure, the rate of strain for the test may be calculated. In the case of cohesive soils, the failure may be assumed as taking place at 5 percent deformation.

FAQs

What is the difference between drained and undrained shear strength?

Following is the difference between below drained and undrained shear strength:

| Drained Shear Strength | Undrained Shear Strength |

|---|---|

| The soil is free to dilate or contract during shear if the soil sample is totally drained. | Whenever water is not allowed to flow in or flow out of the soil then the stress path is called as undrained stress path. |

| In drained condition, the pore water can easily drain out from the soil matrix. | In undrained condition the pore water is unable to drain out or the rate of loading is much quicker than the rate at which the pore water is able to drain out. |

What is the importance of direct shear test of soil?

For any soil, Cohesion (C) and Angle of Internal Friction (Ø) are the two important engineering properties which indicate the shear strength of soil. These two parameters are required for design of slopes, calculation of bearing capacity of any strata, calculation of consolidation parameters and in many other analyses. Direct shear test of soil is used to predict these parameters quickly, especially in cohesionless soils.