What is Setting Time of Cement Paste?

Setting time of cement paste is that the

interval during which the cement paste losses its plasticity after adding water

in cement.

Setting time of cement is calculated in two parts:

(1) Initial setting time of cement and

(2) Final setting time of cement.

Initial

setting time is regarded as the time elapsed between the moments that the water

is added to the cement to the time that the paste starts losing its plasticity

and the hardening of the cement starts. It is the time within which the cement can

be molded in any desired shape without losing its strength.

The final setting time is the time elapsed

between the moment when water is added to the cement and the time when the

paste has completely lost its plasticity and has attained the sufficient

firmness to resist certain and definite pressure. This is the time taken for

the cement paste to becomes hard and attain the shape of the mould in which it

is cast.

|

| Vicat-Apparatus-Diagram |

Determination of Initial Setting Time and Final Setting Time of Cement as per IS: 4031 (Part 5)-1988

Hi friends, you are welcomed in the world

of Civil Allied Gyan. Read definition,

apparatus, IS code, test procedure, formula, result and lab report about initial

and final setting time of cement by Vicat apparatus.

- IS: 4031 (Part 5)-1988, Methods of physical test for hydraulic cement paste

- IS: 5513-1996, For specification for Vicat’s apparatus

- Vicat’s apparatus conforming to IS: 5513-1976

- Plunger

- Glass plate

- Weighing Balance of capacity 1000g and sensitivity to 1g.

- Gauging trowel conforming to IS: 10086-1982.

- Stop Watch

- Dial Gauge

The Vicat’s apparatus for consistency test of cement

paste consists of a frame having a movable rod with a

cap at one end and at the other end any one of the following attachment, which

are interchangeable:

- Needle for determining the initial setting time

- Needle for determining the final setting time

- Plunger for determining the standard consistency

The other two needles are made to freely fall

into a Vicat mould filled with the cement paste and the amount of penetration

of the needles of plunger of 10 mm diameter can be noted using the vertical

graduations from 0 mm to 50 mm.

Read also

Sampling and

Selection of Test Specimen:

The samples of the cement shall be taken as per IS: 3535- 1986*

and the relevant standard specification for the type of cement being tested.

Mix thoroughly the cement sample before testing.

Temperature and Humidity:

Unless otherwise specified this test shall be

conducted at a temperature 25ºC to 29ºC and the relative humidity of laboratory

should be 60% to 70%.

The moist closet or moist room shall be maintained

at 25ºC to 29ºC and at a relative humidity equal to or more than 90%.

|

| Vicat Apparatus |

Preparation

of Test Block

- Before testing the setting time of cement, do the consistency test to obtain the required quantity of water to give the paste normal consistency.

- Prepare a neat 300 g cement paste by gauging the cement with 0.85 times the water required to give a paste of standard consistency. Potable or distilled water will be used in preparing the cement paste.

- Take care that the time of gauging is not less than 3 minutes, not more than 5 minutes and the gauging will be completed before setting occurs.

- The gauging time will be counted from the time

of adding the water to the dry cement until starting to fill the mould. Record

this time (T₁).

- Fill the Vicat mould with a cement paste gauged as above and also the mould resting on a nonporous plate.

- Fill the mould completely and smooth off the surface of the cement paste making it level with the top of the Vicat mould.

- In filling, the mould operators hands and the blade of the gauging trowel will only be used.

- After moulding, immediately place the test block within the moist closet or moist room and allow it to remain there except when determinations of the time of setting are being made.

Determination

of Initial Setting Time of Cement

- Place the test block confined in the mould and resting on the non-porous plate, under the rod bearing lower the needle gently until it comes in touch with the surface of the test block and quickly release, allowing it to penetrate into the test block.

- In. the beginning, the needle will completely pierce the test block.

- Repeat this procedure until the needle, when brought in touch with the test block and released as described above, fails the to pierce the block beyond a point 4.5 mm to 5.5 mm measured from the bottom of the mould.

- The period elapsing between the moments when the cement is mixed with water and the moment at which the needle fails to pierce the test block beyond a point 4.5 mm to 5.5 mm measured from the bottom of the mould will be the initial setting time of the cement paste.

- Record this time (T₂).

Determination

of Final Setting Time of Cement

- Replace the needle of the Vicat apparatus by the needle with an annular attachment.

- The sample of cement paste will be considered as finally set when, upon applying the needle gently to the surface of the test block, the needle makes an impression there on, while the attachment fails to do so.

- The period elapsing between the time when the cement is mixed with water and the time at which the needle makes an impression on the surface of test block while the attachment fails to do so will be the final setting time of the cement paste.

- Record this time (T₃).

Note: In the event of a scum

forming on the surface of the test block, use the underside of the block for

the determination of setting time of cement.

Observations:-

1. Type

of cement =…………………….

2. Brand

of cement = …………………..

3. Weight

of given sample of cement is =…………… ….g

4.

The normal consistency of a given sample of cement paste is = …………...%

5.

Volume of the water added for preparation of test block = ………………ml

Table:-

Sl. No.

|

Setting

Time

(min)

|

Penetration

(mm)

|

1

|

||

2

|

||

3

|

||

4

|

||

5

|

||

6

|

Calculation:-

Initial setting time = T₂ - T₁

Final setting time = T₃ - T₁

Where,

T₁

=

Time at which water is first added to cement

T₂

=

Time when needle fails to penetrate 5 mm to 7 mm from bottom of the mould

T₃

=

Time when the needle makes an impression but the attachment fails to do so.

Result:-

1. The initial setting time of the cement paste

sample is found to be ……….. minutes.

2. The final setting time of the cement paste sample

is found to be ……….. minutes.

Report:-

The results of initial setting

time and final setting time of cement is reported to the nearest five

minutes.

- Clean the apparatus thoroughly before testing and after testing.

- The test should be performed away from vibrations and other disturbances.

- Care should be taken to maintain the specified temperature, humidity and the time of mixing so as to avoid setting of cement paste as per test requirement.

- Clean appliances should be used for gauging and gauging time should be strictly observed.

- Care shall be taken to keep the

needle straight and clean.

- The initial and final setting time needles should be released gently.

- Position of the Vicat mould should be shifted slightly after each penetration to avoid penetration at the same place.

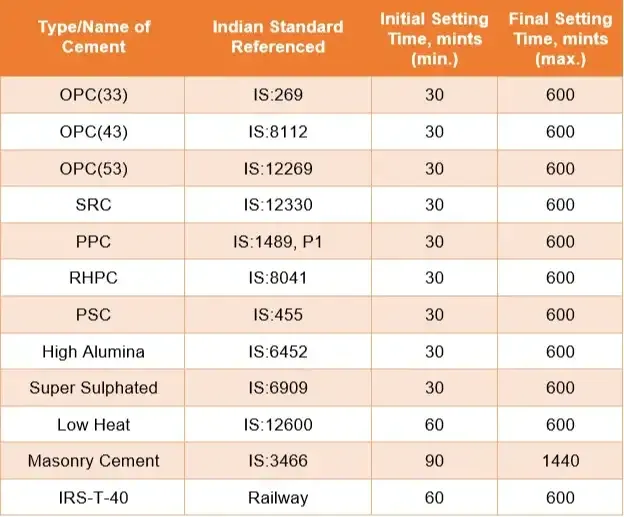

Table:

Indian

Standard Specification of Cement

Value

of Initial and Final Setting Time for Ordinary Portland Cement (OPC):

The initial

setting time for OPC, SRC, PPC, RHPC and PSC is 30 minutes. The final

setting time for OPC, SRC, PPC, RHPC and PSC is 600 minutes.

Initial and final setting time of cement measured by:-

Initial and final setting time of cement measured by vicat's apparatus. The initial setting time for OPC, SRC, PPC, RHPC and PSC is 30 minutes. The final setting time for OPC, SRC, PPC, RHPC and PSC is 600 minutes.

that great posting your post better then https://civiltechnologist.com/setting-time-cement-test/

ReplyDeletegood bro keep it up