What is this blog post about?

Dear readers, in this blog post we have covered the definition, IS code, apparatus list and test procedure of compressive strength test of cement. The calculation and compressive strength test of cement mortar lab report also mentioned here. Just scroll down and learn about this.

A Short Overview on Compressive Strength of Cement

The compressive strength is an important and useful property of cement also of concrete. Here we learn that of cement. It tells how the quality of the cement is, especially about its strength. One can find the compressive strength test of cement by IS: 4031 (Part 6) – 1988 which is fully described here in this article. This method covers the procedure for determining the strength of cement as represented by compressive strength test on mortar cubes compacted by means of standard vibration machine.

Compressive Strength Test of Cement as per IS 4031 Part-6

Read here the definition, apparatus list, IS code, test procedure, formula, result, lab report and significance of compressive strength test of cement.

Compressive Strength of Cement: Definition

The compressive strength is an important and useful property of cement also of concrete. Here we learn that of cement. It tells how the quality of the cement is, especially about its strength. One can find the compressive strength test of hydraulic cement other than masonry cement by IS: 4031 (Part-6) 1988 which is fully described here in this article.

IS Code for Compressive Strength Test of Cement

Compressive strength test of cement is done with Indian Standard code IS: 4031 (Part-6) 1988.

Materials Required for Compressive Strength Test of Cement

- Cement; accordance with the requirements of IS: 3535- 1986.

- Standard sand; conform to IS: 650-1966.

- Water; as per requirement.

Generally, the compressive strength test of cement is performed for 3 days, 7 days and 28 days. Each test requires 3 cubes of size 70.6 mm. For one cube, 200 g cement and 600 g standard sand are used. Therefore 600 g cement and 1800 g standard sand are required for each test (3 days, 7 days or 28 days).

Apparatus List for Compressive Strength Test of Cement

- Compression Testing Machine

- Vibration Machine – conforming to IS: 10080-1982.

- Poking Rod – conforming to IS: 10080-1982

- Cube Mould – 70.6 mm sized and conforming to IS: 10080-1982.

- Weighing Balance – 1.0 g permissible variation at a load of 1000 g.

- Gauging Trowel – having a steel blade 100 to 150 mm in length with straight edges weighing (210 ± 10) g.

- Graduated Glass Cylinders – 150 to 200 ml capacity with ± 1 ml variation.

- Stopwatch

- Dial Gauge

- Humidity Chamber

Compressive Strength of Cement Cube Size

Cube Moulds of size 70.6 mm and conforming to IS: 10080-1982 are used to mould cube for compressive strength of cement test. Area of the each face of cubes should be 50 cm².

Temperature and Humidity:-

- The temperature of moulding room, dry materials and water will be maintained at 27±2 °C. The relative humidity of the laboratory will be 65±5 percent.

- The moist closet or moist room will be maintained at 27±2 °C and at a relative humidity of not less tan 90 percent.

Preparation of Test Specimens

The preparation of test specimens for compressive strength of cement test is done in three parts.

(i) Mixing specimens with standard sand and water,

(ii) Moulding specimen and

(iii) Curing specimen.

Mixing specimens with Standard Sand and Water

- Take quantity of cement, standard sand and water as follows: cement 200g, standard sand 600g and water (p/4+3.0) percent of combined mass of cement and sand, where p is the percentage of water required to produce a paste of standard (or normal) consistency.

- Place the mixture of cement and standard sand on a nonporous plate.

- First, mix cement and standard sand with a trowel in dry form for one minute and then add water and mix them until the mixture is going to be as of uniform colour. The quantity of water to be used will be as specified in step-2.

- The time of mixing will in any event be not less than 3 minutes and if the time taken to obtain a uniform colour exceeds to 4 minutes, the mixture will be rejected and the whole operation will be repeated with a fresh quantity of cement, sand and water as mentioned in step 1.

Note: (i) Use clean appliances for mixing. (ii) Use distilled water in preparing the cubes. (iii) The temperature of water and that of the test room at the time when the above operations are being performed must be (27 ± 2) °C. (iv) For each cube materials should be mixed separately.

Moulding Specimens

- In assembling the moulds ready for use, treat the interior faces of the mould with a thin coating of petroleum jelly or similar mould oil.

- Place the assembled mould on the table of the vibration machine and hold it firmly in position by means of an appropriate clamp.

- Attach a hopper of suitable shape and size securely at the top of the mould to facilitate filling and this hopper will not be removed until the completion of the vibration period.

- Immediately after mixing the mortar in accordance with step 1, 2 and 3, place the mortar within the cube mould and prod with the poking rod.

- The mortar should be prodded 20 times in about 8 second to ensure elimination of entrained air and honey-combing.

- Place the remaining quantity of mortar in the hopper of the cube mould and prod with poking rod again for the first layer and then compact the mortar by vibration machine.

- The period of vibration will be two minutes at the specified speed of (12000 ± 400) vibrations per minute.

- At the end of vibration, remove the mould together with the base plate from the machine and finish the top surface of the cube in the mould by smoothing the surface with the blade of a trowel.

Curing Specimens

- Keep the filled moulds in moist closet or moist room for 23 to 24 hours after completion of vibration.

- At the end of that period, remove them from the moulds and immediately submerge in cleaned fresh water and keep there until taken out just before breaking.

- The water in which the cubes are submerged will be renewed every 7 days and will be maintained at a temperature of 27±2 °C.

- After they have been taken out and until they are broken, the cubes will not be allowed to become dry.

Procedure for Testing Compressive Strength of Cement

- Test three cubes for compressive strength for each period of curing mentioned under the relevant specifications (i.e. 3 days, 7 days and 28 days) for different hydraulic cements, the periods being reckoned from the completion of vibration.

- The cubes will be tested on their sides without any packing between the cube and the steel platens of the testing machine.

- One of the platens will be carried on a base and will be self-adjusting, and the load will be steadily and uniformly applied, starting from zero at a rate of 35 N/mm²/min.

Observations:-

- Type of cement = ........................

- Brand of cement = ........................

- Date of casting = ..........................

Observation Table:-

Calculations

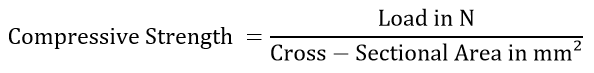

The measured compressive strength of the mortar cubes will be calculated by dividing the maximum load applied to the cubes during the test by the cross-sectional area, calculated from the mean dimensions of the section. The value of compressive strength will be expressed to the nearest 0.5 N/mm².

Formula for Compressive Strength of Cement Test

Result

The average compressive strength of the given cement mortar cubes are

1.) 3 days ………………………. N/mm² 2.) 7 days …………………….. N/mm²

3.) 28 days ……………………… N/mm²

Report

The average values of compressive strength (3 days, 7 days and 28 days) of the three mortar cubes is reported to the nearest 0.5 N/mm².

- Specimens that are manifestly faulty, or that give strengths differing by more than 10% from the average value of all the test specimen should not be considered.

- After discarding specimens or strength values, if less than two strength values are left for determining the compressive strength at any given period, a retest will be made.

Compressive Strength of Cement Mortar After 3 Days, 7 Days and 28 Days

Values of Compressive Strength of Cement Mortar as per Standard Specifications:-

Safety and Precautions While Testing:

- Clean the apparatus thoroughly before testing and after testing.

- The test should be performed away from vibrations and other disturbances.

- Wear helmet, shoes and hand gloves during the test.

- The moulds should be oiled before the experiment.

- The weighing should be done accurately.

- The temperature and humidity must be accurately controlled.

- Increase the load gradually during testing.

- The cement mortar cubes should be tested immediately after taking out of water and not allowed to dry until they fail under testing.

- The gauging time should be strictly observed.

- The cubes should be tested on their sides and not on their faces.

Significance of Compressive Strength Test of Cement

- The compressive strength of cement mortar cubes or concrete is one of the most important and useful property.

- The compressive strength of cement mortars is determined in order to verify whether the cement conforms to Indian Standard (IS, or other standards like ASTM, BS etc.) specifications and whether it will be able to develop the concrete of required compressive strength.

- The compressive strength test is done on cement, when it is used as cement mortar and concrete.

- As a construction material, concrete is employed to resist the compressive stresses. While, at locations where tensile-strength or shear-strength is of primary importance, the compressive strength is used to estimate the required property of cement mortar cubes.

- The mixture of cement and sand in water is generally weak in tension but it is strong in compression when it is subjected to tensile tension with iron rods. The mortar is used for plastering and brick masonry. The first case gives mortar heavy load in form of construction on it by placing bricks on mortar .that is why, it is important to know the strength of the mortar.

- The strength of the binder (cement) therefore has a significant effect on the performance characteristics of the mixture of cement and sand and ensures the overall quality of the finished product.

Dependence of Compressive Strength of Cement Mortar

The mixture of cement and sand are in pre-defined ratios and the compressive strength of the mortar depend on the quality of the cement, the gradation of sand used in mixture and the water–cement ratio.

The compressive strength of cement or mortar cube depends on the strength and weakness of the mortar cube. If mortar cube is weak then the compressive strength of the mortar cube is also weak. If mortar cube is strong, then the compressive strength of the mortar cube will be high.

FAQs

What is Compressive Strength of Cement Mortar?

The compressive strength is an important and useful property of cement also of concrete. It tells how the quality of the cement is, especially about its strength. One can determine the compressive strength of cement using method described above in this article.

How Compressive Strength of Cement is Determined?

Compressive strength of cement is determined by the test named after it and covered in IS: 4031 (Part-6) which is described above in this blog post. This method covers the procedure for determining the strength of cement as represented by compressive strength test on mortar cubes compacted by means of standard vibration machine. Standard sand (as per IS: 650) is used for the preparation of cement mortar cubes.

How to calculate compressive strength of cement mortar cube?

The measured compressive strength of the cubes is calculated by dividing the maximum load applied to the mortar cubes during the test by the cross-sectional area, calculated from the mean dimensions of the section.

The average compressive strength of at least three cement mortars cubes (area of the face 50 cm²) composed of one part of cement and the other three parts of standard stand should satisfy IS code specifications.