What is Heavy Compaction Test of Soil?

Heavy compaction test of soil is

carried out using modified proctor test to understand the compaction

characteristics of different types of soils with change in moisture content (water

content).

The Proctor compaction test (or heavy

compaction test) is a laboratory test which is used for experimentally

determining the optimal moisture content (O.M.C.) of soil at which the given type

of soil specimen will become most dense and achieve its maximum dry density (by

removal of air voids).

This test is named in the honor of Ralph Roscoe

Proctor. In 1933, he showed that the dry density of a soil for a given

compactive effort depends on the amount of water contained by the soil during soil

compaction test. His original test is commonly referred as the standard proctor

compaction test. His test was later updated to create the modified proctor

compaction test for soil.

What

is Heavy Compaction of Soil?

Compaction of soil is the optimal moisture

content (O.M.C.) at which the given type of soil specimen becomes most dense

and achieve its maximum dry density by removal of air voids.

HEAVY COMPACTION TEST OF SOIL, MODIFIED PROCTOR TEST PDF, IS: 2720 (PART 8): 1983

Scope: To determine the water

content-dry density relation of soil using heavy compaction.

IS CODE FOR HEAVY COMPACTION TEST OF SOIL OR MODIFIED PROCTOR TEST:-

- IS: 2720 (Part 8): 1983, Methods of test for soils: Determination of water content (moisture content) and dry density relationship using heavy compaction test

APPARATUS REQUIRED FOR THE HEAVY COMPACTION TEST OF SOIL OR MODIFIED PROCTOR TEST:-

- Cylindrical Metal Mould 100 mm diameter and 1000 cm³ volume or 150 mm diameter, and 2250 cm³ volume.

- Sample Extruder (Optional).

- Balances–One of capacity 10 kg and sensitive to 1 g & other of capacity 200 g and sensitive to 0.01 g.

- Oven–Thermostatically controlled with interior of non-corroding material to maintain the temperature between 105ºC & 115ºC.

- Non corrodible containers (Airtight containers)

- Steel straightedge–A steel straightedge of length about 30 cm and having one bevelled edge.

- Sieve: 4.75-mm and 19-mm and 37.5-mm IS sieves.

- Mixing Tools–Tray or pan, spoon, trowel and spatula.

- Metal Rammer - 4.9 kg rammer failing through a height of 450 mm is used.

PROCEDURE OF THE HEAVY COMPACTION TEST OF SOIL OR MODIFIED PROCTOR TEST:-

A) For soil sample not susceptible to crushing during compaction.

- A 5-kg sample of air-dried soil passing the 19 mm IS test sieve will be taken.

- A suitable amount of water will be mixed thoroughly with the sample. The amount of water depends on the soil type. For sandy and gravelly soil the amount of water to be added should be 3 % to 5 % of water. For cohesive soil add 12 % to 16 % below the plastic limit of the soil.

- The mould, with base plate attached, will be

weighed to the nearest 1 g (M1).

- The mould will be placed on a solid base, such as a concrete floor or plinth and the moist soil will be compacted into the mould, with the extension attached, in five layers of approximately equal mass, each layer being given 55 blows from the rammer.

- The blows will be distributed uniformly over the surface of each layer.

- Care is taken by the operator to ensure that the tube of the rammer is kept clear of soil so that the rammer always falls freely.

- The amount of soil used will be sufficient to fill the mould, leaving not more than about 6mm to be struck off when the extension is removed.

- The extension will be removed and the compacted soil will be levelled off carefully to the top of the mould by means of the straightedge.

- The mould and soil will then be weighed to 1 g (M₂).

10. The compacted soil specimen will

be removed from the mould and placed on the mixing tray.

11. The water content of a

representative sample of the specimen will be determined.

12. The remainder of the soil

specimen will be broken up, rubbed through the 19-mm lS test sieve, and then

mixed with the remainder of the original sample.

13. Suitable increments of water will

be added successively and mixed into the sample, and the above procedure will

be repeated for each increment of water added.

14. The total number of

determinations made will be at least five, and the range of moisture contents

should be such that the optimum moisture content, at which the maximum dry

density (MDD) occurs, is within that range.

B) For soil sample susceptible to crushing during compaction:

- Five or more 2.5 kg sample of air dried soil passing 19 mm IS test sieve will be taken.

- The samples will be mixed thoroughly with different amount of water to give a suitable range of moisture contents.

- The range of moisture content at which the maximum dry density (MDD) occurs is within the range.

- Remaining process is the same.

C) For compacting soil in large mould:

- For compacting soil containing coarse material up to 37.5 mm size, the 2250 ml (= 2250 cm³) mould should be used.

- A sample weighing about 30 kg and passing 37.5 mm sieve is used for test.

- Soil is compacted in 5 layers, each layer being given 55 blows of the 4.9 kg rammer.

- The rest of the procedure are the same.

CALCULATION:-

A.) Bulk density, Υм in

g/cc, of each compacted specimen will be calculated from the equation:

Where,

M1 = mass

in g of mould and base;

M₂

=

mass in g of mould, base and soil; and

Vм =

volume in ml of mould.

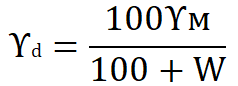

B.) The

dry density, Υd in

g/ml, will be calculated from the equation:

Where,

W = moisture content of soil in percent.

GRAPH:-

The dry densities, Υd, obtained in a series of

determinations is plotted against the corresponding moisture content ‘M’. A

smooth curve is then drawn through the resulting points and the position of the

maximum value on this curve is determined, which is called the maximum

dry density (M.D.D.). And the corresponding moisture content is

called the optimum moisture content (O.M.C.) or optimum moisture

content (O.P.C.).

|

| Fig. Compaction Curve |

REPORT:-

The experimental points and the smooth curve

drawn through them showing the relationship between moisture content and dry

density will be reported.

The dry density in g/cc corresponding to the peak

point of the compaction curve (water content-dry density curve) will be

reported as the maximum dry density (M.D.D.) to the nearest 0.01.

The percent moisture content corresponding to

maximum dry density (M.D.D.) on the peak point of the compaction curve will be

reported as optimum moisture content (O.M.C.) to the nearest 0.2 for values

below 5%, to nearest 0.5 for values 5-10% and whole number for values above

10%.