What is The Flakiness Index of Aggregate?

The flakiness index of aggregate is defined

as the percentage by mass of particles (stones) in it whose least dimension

(thickness) is less than three-fifths of their average dimension.

Flakiness index of aggregate test is

conducted on coarse aggregates sample to estimate the shape of aggregates.

Thus, evaluation of shape of the aggregate particles,

particularly with reference to flakiness and elongation is necessary.

The flakiness index of an aggregate

sample is found by separating the flaky aggregates by sieving. Flakiness index is

expressed as their weight as a percentage of the weight of the sample tested.

The test flakiness index of aggregate is

not applicable to the materials passing through the 6.30 mm IS test sieve or

retained on the 63.00 mm IS test sieve.

Flakiness Index of Aggregate, Shape Test of Aggregates, IS: 2386 (Part 1)-1963

Hi friends, you are welcomed in the world

of Civil Allied Gyan. Here

I have explained about the test flakiness index of coarse aggregate.

By the help of this you can easily perform

the test flakiness index of coarse aggregate. So please continue to the end

& keep your love and support on me.

Apparatus

Required For The Test Flakiness Index of Aggregate:

- Thickness gauge

- Weighing balance

- Gauging trowel

- Sieves

- IS: 2386 (Part 1)–1963, Method of test of aggregates for formation of concrete

- IS: 383–1970, Specification for coarse and fine aggregate from natural source for formation of concrete

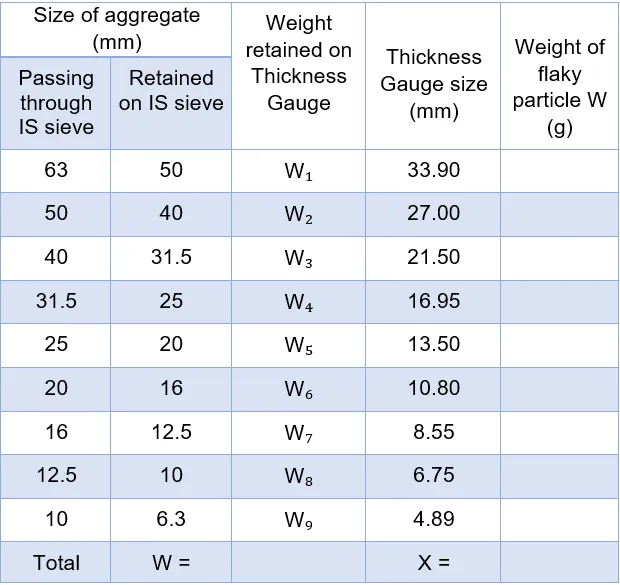

- Sieve the aggregate sample with sieves specified in Table.

- Take sufficient quantity of aggregate to provide the minimum number of 200 pieces of any fraction to be tested.

- Then to separate the flaky materials, gauge each fraction for thickness on a thickness gauge of the pattern shown in Fig or in bulk on sieves having elongated slots.

- The width of the slot used in the thickness gauge or sieve should be of the dimensions specified in column 4 of Table for the appropriate size of material.

- Weigh the total amount of flaky material passing

the gauge to an accuracy of at least 0.1 percent of the weight of the test

sample.

Calculations

and Observations:-

Formula

for flakiness

index of aggregate:

Where,

X = The weight of material passing through the

various thickness gauges and

W = The weight

of aggregate passing and retained on the specified sieves.

Table: Dimensions of Thickness

Results:

Flakiness index of aggregate =

.................

Note:-

Surface texture and aggregate shape influence

the properties of freshly mixed concrete more than the properties of hardened

concrete. Rough-textured, angular and elongated aggregates require more water

to produce workable concrete than smooth, rounded compact aggregates.

Consequently, the cement contents must also

be increased to maintain the water-cement (W/C) ratio. Generally, flat and

elongated aggregate particles are avoided or are limited to about 15 % by

weight of the total aggregate.

Recommended

Values of Flakiness Index and Elongation Index

The aggregate shape tests give only a rough

idea of the relative shapes of aggregates. Flaky and elongated aggregate particles

should be avoided in pavement construction, particularly in surface course.

If the flaky and elongated aggregate particles are present in

appreciable proportions, the strength of pavement construction’s layer would be

adversely affected due to probability of breaking down under heavy loads. Workability of cement

concrete is reduced. IRC recommendations for maximum limits of flakiness index

are as given below.

Sl. No:

|

Type

of pavement

|

Maximum

limits of flakiness index, %

|

1

|

Bituminous

carpet

|

30

|

2 (i)

|

Bituminous

/ Asphaltic concrete

|

25

|

(ii)

|

Bituminous

Penetration macadam

|

|

(iii)

|

Bituminous

surface dressing (single coat, double coats and precoated)

|

|

(iv)

|

Built

up spray grout

|

15

|

3

(i)

|

Bituminous

macadam

|

|

(ii)

|

WBM

base course and surface course

|

The test flakiness index of aggregate is

used to determine the particle shape of the aggregate specimen and each particle

shape being preferred under specific condition.

The significance

of flakiness and elongation index of aggregate are following:

- The degree of packing of the aggregate particles of one size depends upon their shape.

- Due to high surface area to volume ratio, the flaky and elongated aggregate particles lower the workability of concrete mixes.

- For cement concrete types and base coarse construction

and bituminous-construction, the presentence of flaky and elongated aggregate

particles are considered undesirable as they may cause inherent weakness with possibility

of breaking down under heavy loads.

- According to BS-1241, a flakiness index should not exceed 30% irrespective of the aggregate size.

- Maximum permitted elongated index is 35%, 40% or 45% for aggregate size 21/2” – 2”, 11/2” - ¾” and 1/2” - ⅜”.

- Both Flakiness index Elongation Index tests are not applicable to the materials of sizes smaller than 6.3 mm i.e. ¼” sieve.

Read also -